Shop

Welcome to my goat owning candle making Etsy shop!

I’m a goat farmer and candle maker from upstate New York. I’ve been making candles since I was a kid, and I started making goat milk soap and candles a few years ago when I got into goat farming. I use only the highest quality, all-natural ingredients in my candles, and I only use goat milk from my own goats.

My candles are made with a combination of beeswax and soy wax. I use a combination of beeswax and soy wax because soy wax is a softer wax and can’t hold as much fragrance oil as beeswax. I also use a higher percentage of beeswax in my candles because it burns cleaner and gives the candle a longer burn time.

I use 100% pure essential oils and fragrances in my candles. I don’t use any synthetic fragrances or dyes in my candles. All of my candles are hand-poured and hand-made. I use only the highest quality ingredients and I take great care in making each and every candle.

I’m a small, family-owned business and I take pride in my candles. I hope you enjoy them!

West Houston Candle Making Classes

Houston, TX

Do you love the smell of candles but don’t know how to make them? Join us for a candle making class in west Houston and we’ll show you how! Our classes are perfect for beginners and we’ll provide all of the supplies you need.

In our classes, you’ll learn how to make three different types of candles – soy wax, beeswax, and paraffin. We’ll also teach you how to make custom scents, and you’ll get to take home your own creations!

Our classes are held in a private studio, and we provide all of the supplies you need. You’ll also get to take home your own creations, so you can enjoy the smell of candles all year long!

If you’re interested in learning more about candle making, or if you want to sign up for a class, please contact us today. We look forward to teaching you everything we know about candle making!

Candle Making Penn Indianapolis

Candle making is an ancient art form that has been used for centuries to provide light, heat and ambiance. The process of making candles can be simple or complex, depending on the type of candle being made. The most basic type of candle is a dipped candle, which is made by dipping a wick in melted wax and then allowing the wax to harden. There are many different types of dipped candles, including taper candles, votive candles, container candles and pillar candles.

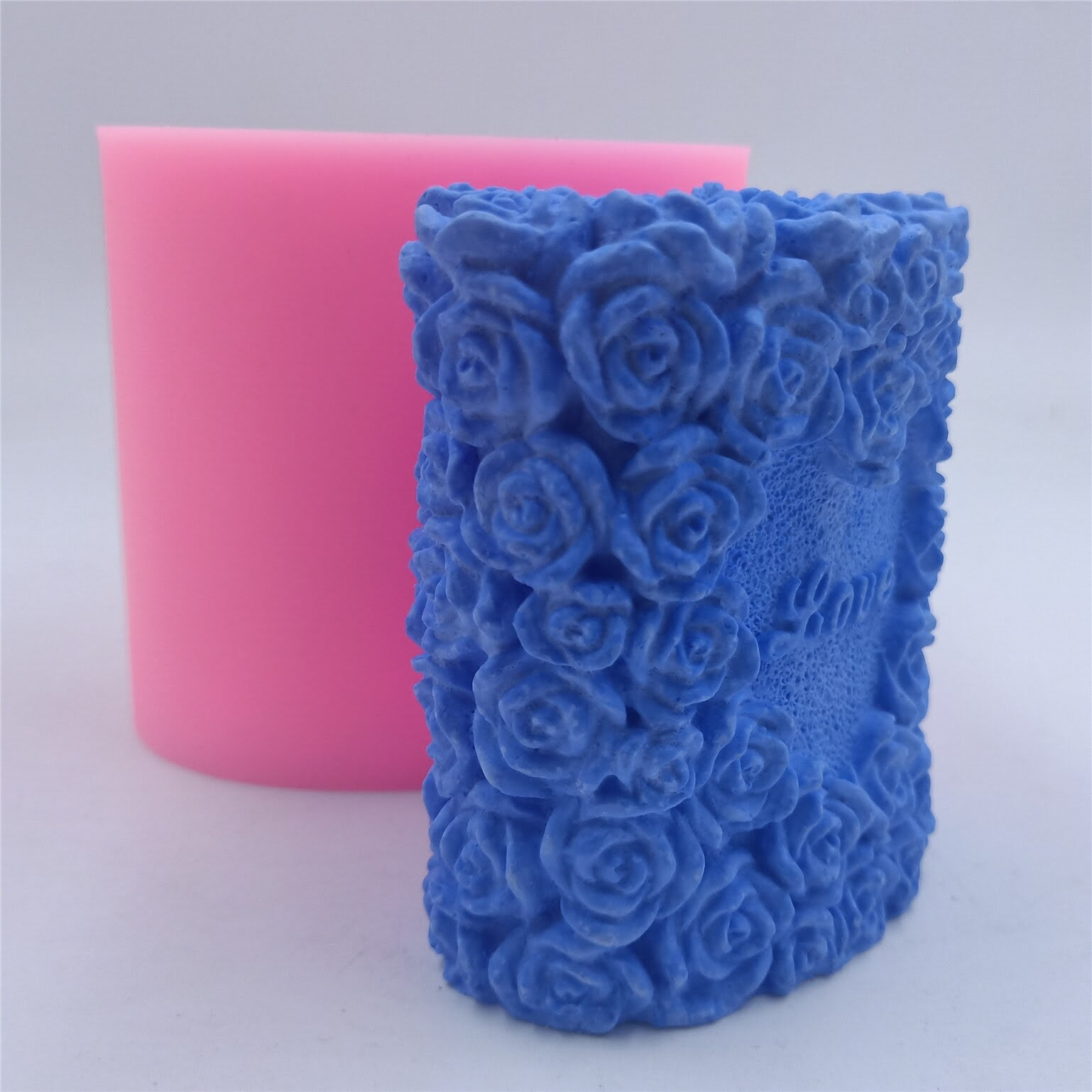

Another common type of candle is the molded candle. Molded candles are made by pouring melted wax into a mold and then allowing it to harden. The most common type of molded candle is the soy candle, which is made from soy wax. Soy candles are environmentally friendly, because they are made from a renewable resource, and they are also biodegradable.

The most complex type of candle is the poured candle. Poured candles are made by pouring melted wax into a container and then allowing it to harden. Poured candles can be made from a variety of different types of wax, including beeswax, soy wax and paraffin wax. Poured candles are often decorated with wax additives, such as glitter or fragrance, to give them a unique look and smell.

No matter what type of candle you are making, there are a few basic steps that you need to follow. The first step is to choose the right type of wax. The type of wax you use will depend on the type of candle you are making and the type of wick you are using. The next step is to melt the wax. You can do this in a variety of ways, including using a microwave, a stovetop or an electric wax melter.

The next step is to thread the wick through the candle. You can do this by using a wick holder or by holding the wick between your thumb and forefinger. The next step is to pour the wax into the container. You can do this by using a pouring pitcher or a measuring cup. The next step is to allow the wax to cool and harden. The final step is to trim the wick to the desired length.

Online Christmas Candle Making

Christmas is a time for family, friends, and of course, Christmas candles! Whether you’re looking for a new tradition to start, or you simply want to get into the Christmas spirit, making your own candles is a great way to do it. And thanks to the internet, it’s easier than ever. Here are a few tips to get you started.

The first step is to choose your wax. For Christmas candles, I recommend using a scented wax, such as soy or beeswax. This will give your candles a festive smell, and will also make them burn more slowly and evenly.

Once you’ve chosen your wax, it’s time to choose your scent. There are a ton of different Christmas scents to choose from, so you’re sure to find one that you love. Some popular options include pine, cinnamon, gingerbread, and vanilla.

The next step is to choose your container. You can use any type of container you like, but I recommend using something festive, like a Christmas mug or a snowman-shaped container.

Now it’s time to get started! The first step is to melt your wax. You can do this by using a microwave or a stovetop. Once the wax has melted, add your scent and stir well.

Now it’s time to pour the wax into your container. Be careful not to pour too much at once, or the candle will be too thick and will take a long time to burn.

Once the wax has been poured, let it cool for a few hours. Once it’s cooled, you can light your candle and enjoy!

Making Paschal Candle Pouring Mold Pvc

1. PVC pipe is a great material for making candle pouring molds because it is cheap, easy to work with, and can be adapted to any size or shape.

2. Start by cutting a piece of PVC pipe to the desired length.

3. Use a saw to cut the pipe into two or more segments, depending on the size of the mold you want to create.

4. Drill a hole in the center of each segment. This will be the hole that the melted wax will flow through.

5. Sand the edges of the pipe segments until they are smooth.

6. Paint the pipe segments with a non-toxic sealant, if desired. This will help to prevent the wax from seeping out of the holes.

7. Allow the sealant to dry completely.

8. Pour melted wax into the holes in the pipe segments.

9. Allow the wax to cool and harden.

10. Remove the wax from the mold.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.