Introduce Further Uses for Beeswax Sheets

Beeswax sheets are a popular choice for making candles in the United Kingdom. With its high melting point, beeswax is easy to work with, making it an ideal wax for many craft projects. In addition to candle making, beeswax sheets can be used for a variety of DIY projects such as encaustic wax art and wax seals, as well as more intricate tasks such as wax carving and wax mold making. Beeswax also has anti-bacterial properties that make it ideal for use in skin care products. There is so much potential when it comes to working with these beautiful sheets of buoyant honeycomb; let your creativity run free!

Demonstration of Techniques

When making candles out of beeswax sheets, an important thing to remember is the use of tips and techniques used in candle making. Below are some useful tips and techniques that can help you make high quality candles out of beeswax sheets:

1. Start by cutting the beeswax sheet into the size and shape you require for your candle. Make sure to measure twice before you cut so as not to waste materials.

2. Gently start to roll up the wax layer by layer along with a rolling pin, until it has a uniform width. Avoid applying too much pressure to avoid forming bubbles in your wax cylinder, as the gas will burn off during the melting process which can create smoke when lit.

3. Heat up a metal mould using an electric heating pad or carefully using a blow torch and slowly insert your rolled-up beeswax cylinder into it until it melts completely, filling all nooks and crannies of the mould evenly with hot melted wax.

4. When all possible air bubbles have been removed from wax, crease or flatten the sides of moulded candle so that they look smooth when viewed at different angles. Now warm wick bases separately until they become malleable and then attach them firmly to specified points on each end of your already created candle frames which acts as a wick holder inside it once completed.

5. Finally, place the cooled shaped candles in cold water bath with constant stirring till they come out cleanly from their moulds indicating completion of this process then hang these ready made candles somewhere away from direct sunlight so that only natural light touches them, thus helping them retain their original shape more effectively over time!

In addition to illustrating how to use these tips and techniques for making high quality beeswax sheets candles, one could demonstrate these steps through video tutorials for a better understanding and easier access for anyone interested in taking on this type of craft project! Video tutorials would be helpful in visualizing any tricky steps or seeing certain measurements at play while performing processes such as cutting, rolling and heat tempering within various contexts of workflows like attaching wicks or getting properly formed shapes out from moulds etc., throughout the entire candle-making journey!

Discuss Different Types of Waxes Available

When making candles with beeswax sheets, it is important to be mindful of the type of wax used for your candle making projects. Generally, there are three types of wax that can be used: paraffin wax, soy wax, and beeswax.

Paraffin Wax: This type of wax is a petroleum-based product and generally provides a softer and more malleable wax for your projects. Paraffin is generally easier to work with than other types of waxes because it melts at a lower temperature. Its low melting point makes it possible to incorporate different dyes or scents quickly.

Soy Wax: Known as an eco-friendly option, soy wax burns cooler and slower than paraffin. Aside from being better for the environment, soy candle makers also enjoy the creamy texture when melting this type of wax, which can make pouring an easy endeavor even without professional equipment. Care should be taken by those inexperienced in candle making because soy can burn at lower temperatures, leading to more rapid carbon build up on wicks if poured too thickly or unstirred between pouring pours.

Beeswax: Beeswax has a wide variety of uses in candle making as it has been used since Ancient Egypt due to its natural aroma and strong flame that doesn’t flicker like other types of waxes. Furthermore bee’s was imparts a glossy finish onto any finished product, adding sheen to both layered creations and hand-dipped items alike. It also has a high melting point which can make it more difficult to work with than other types of waxes but is beneficial when needing greater strength on votives and taller containers as they won’t melt down so quickly during warmer days or periods in use. An additional benefit lies in the success experienced by many in their ability to add plant-based dyes directly into the melting pot for added coloring options no matter what type you choose for your project.

Outline Different Styling and Finishing Techniques

Styling:

One way to style wax sheets for candles is by rolling them up. Start by heating up the sheet with a heat gun or a candle warmer and then carefully stretch it out to its desired size. Once heated, shaping can be done by wrapping the sheet around a mold of your choosing, or winding it around a cylinder such as the handle of a spoon, before allowing it to cool in place. Another styling technique which works well with beeswax is layering ” cut out two strips of different colors of beeswax, use one as an inner layer and the other as an outer lining, creating stripes with alternating heights and colors.

Finishing:

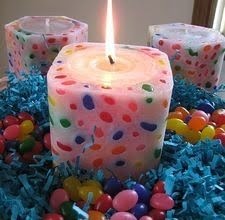

Once you’re satisfied with the shape of your candle you can move onto the finishing process. Adding etches, cuts, ridges or grooves are all effective ways to add texture, if this isn’t something you’re comfortable doing through carving then decorative wax stamps can help achieve this look. Alternatively adding cosmetic elements such sprinkle glitter on top or pieces of small stones will help enhance this look further. To finish off Beeswax candles usually feature simple natural finishes such as tying string around each end for that rustic farmhouse feel or personalizing them with a monogram of your choice ” there’s endless possibilities when it comes to wax sheets for candles!

Advisory for Beginners

Beeswax sheets for candle making in the UK can be a tricky hobby to become adept at, especially for beginners. There is a range of things to consider when using beeswax forcandle making, such as choosing the correct type of wax and using good quality wicking supplies. Additionally, you must also understand the methods of melting and pouring correctly without causing damage to the beeswax sheet. Beginners must ensure that they read up on candle making tutorials before attempting beeswax sheets for candle making in their own home. There are some great online resources available with helpful tips, advice and step-by-step instructions that cater specifically to the use of beeswax for candle making. It is essential for any beginner using this method to practice caution and bookmark useful sites so they can refer back to them when needed. With patience and perseverance, it won’t be long until you become an expert at crafting beautiful candles with beeswax!

Use of Essential Oils to Scent Candles

Many essential oils can be used to scent beeswax sheets for candle making in the UK. To do this, begin by heating the beeswax sheets until they become soft and pliable. On a baking tray, cover the sheet with a single layer of essential oil droplets. Be sure not to leave any uncovered spots as these are areas that won’t absorb any scent when heated. Once the sheet is completely covered, place it onto the preheated oven tray and allow it to bake for 10-15 minutes at a low temperature (about 120C). Allow the sheet to cool before touching it or using it as your candle wax bases. When melted together while in liquid form, these sheets will create scented candles with your choice of fragrant oil blend!

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.