Choosing the right wick for beeswax candles is crucial to achieving optimal burn and fragrance release. The wick selection directly impacts the overall quality and performance of the candle.

In this article, we will delve into various factors that should be considered when selecting a wick for beeswax candles, including candle diameter, desired burn time, and specific fragrance requirements. We will also explore the essential characteristics that the best wick for beeswax candles should possess, such as a robust cotton or natural fiber core, proper thickness, and minimal carbon buildup.

Additionally, we will discuss different types of wicks commonly used for beeswax candles and provide top recommendations for the best wicks tailored specifically for beeswax candles. If you’re interested in making your own custom wicks at home or troubleshooting any potential issues related to wicks, we’ve got you covered with step-by-step guides and practical tips. Join us on this journey to discover the best wick options for your beeswax candle-making endeavors.

Factors to consider when selecting a wick for beeswax candles

When it comes to selecting the right wick for beeswax candles, there are several important factors that should be taken into consideration. These factors play a crucial role in determining the optimal burn time, fragrance release, and overall performance of the candle. By understanding these factors and their influence on the wick’s size, material, and construction, you can ensure that you choose the perfect wick for your beeswax candles.

Candle diameter

One of the first factors to consider when selecting a wick for your beeswax candles is the candle’s diameter. The size of the wick needs to be proportionate to the size of your candle in order to achieve an efficient and even burn. A wick that is too small may result in tunneling – where only a small portion of the wax melts, leaving excess wax around the sides.

On the other hand, a wick that is too large may cause excessive smoke and dripping. Therefore, it is essential to carefully match your wick diameter with your candle diameter.

Burn time

Another important factor to consider is the desired burn time of your beeswax candle. If you prefer a longer burning candle, you would need a slower-burning wick. This can be achieved by choosing a thicker or tightly braided wick which will provide more fuel (wax) to sustain a longer burn time. Conversely, if you desire a shorter burn time for smaller candles or votives, a thinner or loosely braided wick would be more suitable.

Specific fragrance requirements

The type and strength of fragrance used in your beeswax candles also influences the choice of wick. Different fragrances have varying flashpoints (ignition points) which require different heat levels for optimal scent throw.

Some fragrances require hotter burns to release their aromas effectively while others may have lower flashpoints and can be overwhelmed by an overly hot flame. It is crucial to take note of the fragrance’s recommendations and consult fragrance suppliers or experienced candle-makers for guidance on wick selection.

Considering these factors when selecting a wick for your beeswax candles will allow you to create candles with optimal burn, fragrance release, and overall performance. By matching the wick diameter to your candle size, determining the desired burn time, and considering specific fragrance requirements, you can ensure that your beeswax candles burn beautifully and provide a delightful sensory experience.

Characteristics of the best wick for beeswax candles

Choosing the right wick for beeswax candles is essential to ensure optimal performance and fragrance release. The characteristics of the best wick play a crucial role in determining the overall quality of the candle. When selecting a wick for beeswax candles, it is important to consider factors such as the candle diameter, desired burn time, and specific fragrance requirements.

A robust cotton or natural fiber core is one of the key characteristics that the ideal wick for beeswax candles should possess. These materials provide strength and stability to support an even burn throughout the candle’s lifespan. Additionally, a proper thickness is important to ensure that the wick can efficiently draw up the melted wax pool, allowing for consistent burning.

Another important characteristic of a good wick is minimal carbon buildup. Beeswax tends to produce less soot compared to other types of wax, but it can still result in carbon buildup if the wick is not suitable. A clean-burning wick with minimal carbon buildup helps maintain a longer lifespan for your candle while also preventing any potential damage caused by excessive smoke or soot.

To summarize, the best wicks for beeswax candles should have a robust cotton or natural fiber core, proper thickness, and minimal carbon buildup. These characteristics contribute to an even burn and efficient fragrance release. It is recommended to consider these factors when selecting a wick for your beeswax candle-making projects.

| Characteristic | Description |

|---|---|

| Robust Core | A strong cotton or natural fiber core that provides stability and even burn. |

| Proper Thickness | An appropriate thickness that allows efficient drawing of melted wax for consistent burning. |

| Minimal Carbon Buildup | A clean-burning wick with minimal carbon buildup to prevent soot and ensure a longer lifespan for the candle. |

Types of wicks commonly used for beeswax candles

When it comes to selecting the right wick for your beeswax candles, it’s essential to understand the different types available in the market. Each type has its own characteristics and performance, making it crucial to choose one that best suits your specific candle-making goals. Here, we will explore some of the most commonly used wick types for beeswax candles.

Square braided wicks

Square braided wicks are often a popular choice among candle makers due to their excellent stability and even burn. These wicks are made by weaving multiple strands of cotton or linen together in a flat, square shape. This construction allows for consistent fuel absorption and controlled flame height, resulting in less soot and a cleaner burn.

Square braided wicks are ideal for medium to large-sized beeswax candles with diameters between 2 to 4 inches. Their robust construction makes them suitable for beeswax’s high melting point and slower burn rate compared to other candle materials. Additionally, these wicks are known for their minimal mushrooming and carbon buildup, which helps maintain the overall quality of your candle.

Flat braided wicks

Flat braided wicks consist of thin, flat fibers tightly woven together. They offer a versatile option for various candle sizes and types, including beeswax candles. The flat design ensures increased rigidity and stability during burning while promoting an efficient fuel draw.

These wicks tend to produce smaller flame sizes compared to square braided ones, making them suitable for smaller beeswax candles or those with thinner diameters. However, they may require slightly more maintenance during burning as they can occasionally exhibit slight curling or leaning due to their construction.

Cotton core wicks

Cotton core wicks are a combination of cotton threads enveloped around a thin piece of braided paper. They are known for their consistent performance and clean burn characteristics, making them a popular choice among candle makers.

The cotton core provides stability and structure to the wick, while the paper braid aids in fuel absorption. This combination ensures an even burn throughout the candle’s lifetime and helps reduce carbon buildup.

Cotton core wicks are suitable for a wide range of beeswax candle sizes, depending on their thickness and construction. They are especially well-suited for containers or pillars with larger diameters, offering an excellent balance between flame size and burn efficiency.

When selecting a wick type for your beeswax candles, it’s important to consider the diameter of your candles, desired burn time, and any specific fragrance requirements. By choosing a suitable wick type based on these factors, you can ensure optimal burn performance and fragrance release in your beeswax candles.

Top recommendations for beeswax candle wicks

When it comes to choosing the best wick for beeswax candles, there are several options available in the market. However, not all wicks are created equal when it comes to maximizing burn time and fragrance release. Here are some top recommendations for beeswax candle wicks that have been specifically designed to enhance the performance of beeswax candles:

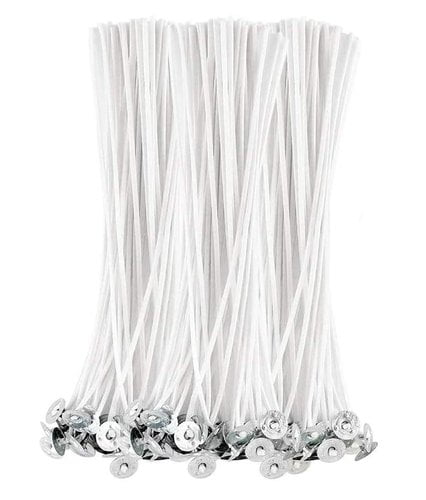

- Cotton core wicks: These wicks are a popular choice for beeswax candles due to their excellent burn stability and minimal carbon buildup. The cotton core provides structural support while ensuring a consistent and even burn throughout the candle’s lifespan.

- Square braided wicks: Square braided wicks offer optimal rigidity and stiffness, making them suitable for larger diameter beeswax candles. They provide a steady flame and efficient burning, preventing tunneling and ensuring maximum wax consumption.

- HTP (High Performance Wick) series: The HTP series is known for its exceptional burn quality and self-trimming properties, making it an ideal choice for beeswax candles. These wicks are made with a unique blend of cotton fibers that ensure clean burning without excessive sooting or mushrooming.

- Wood wicks: For those looking to add a touch of uniqueness to their beeswax candles, wood wicks can be a great option. These natural wooden wicks create a soothing crackling sound reminiscent of a cozy fireplace while providing an even burn.

- Eco-friendly options: If sustainability is important to you, consider using eco-friendly wick options such as hemp or organic cotton wicks. These choices not only ensure a clean burn but also align with environmentally conscious practices.

Overall, when selecting the best wick for your beeswax candles, consider factors such as desired scent throw, burn time, candle diameter, and personal preferences. It’s essential to test different types of wicks in small batches before committing to larger-scale production to ensure the desired results. Remember, choosing the right wick is crucial for achieving optimal performance and enjoying a quality beeswax candle experience.

| Wick Type | Description |

|---|---|

| Cotton core wicks | Sturdy and minimal carbon buildup |

| Square braided wicks | Rigidity for larger diameter candles, even burn |

| HTP (High Performance Wick) series | Clean burn, self-trimming properties |

| Wood wicks | Adds unique crackling sound, even burn |

| Eco-friendly options (Hemp or organic cotton) | Sustainable choice, clean burn |

Tips for wick testing and troubleshooting

When it comes to making beeswax candles, choosing the right wick is crucial for achieving optimal burn and fragrance release. However, finding the perfect wick for your beeswax candles can be a bit of a trial and error process. This section will provide some valuable tips on wick testing and troubleshooting to ensure that you select and use the best wick for your candles.

Conducting Wick Testing

Before settling on a particular wick for your beeswax candles, it’s important to conduct thorough testing to determine its performance. Follow these steps to effectively test your wicks:

- Choose candle diameter: Select the appropriate candle diameter that matches your desired finished product.

- Trim the wicks: Trim all the wicks to the same length, typically around 1/4 inch (6mm).

- Burn time: Light each candle simultaneously and record how long it takes for them to achieve a full melt pool (where wax reaches the edges of the container).

- Flame height: Observe and compare the flame heights of each candle. The ideal flame should be stable with minimal flickering or smoking.

- Scent throw: Evaluate how well each candle releases its fragrance. Make note of any variations in scent strength or diffusion.

Troubleshooting Common Issues

Even with proper testing, you may still encounter common issues related to wicks when making beeswax candles. Here are some troubleshooting techniques for addressing these problems:

- Mushrooming: If you notice excessive mushrooming at the top of your wick resulting in soot or smoke, try trimming the wick shorter or choosing a smaller size.

- Tunnelling: Tunnelling refers to uneven burning where the wax tunnels down the center while leaving unmelted wax on the sides. To prevent this, choose a larger wick size that provides sufficient heat to melt the wax evenly.

- Poor scent throw: If your candles are not releasing enough fragrance, it may indicate an inadequate wick size. Consider using a larger wick to ensure proper fragrance diffusion.

- Inconsistent burn time: Uneven burn times can be attributed to factors such as draft or improper wick size. Make sure your candles are placed away from any drafts and test different wick sizes until you achieve consistent burn times.

Remember, each candle-making project is unique, and finding the right wick for your beeswax candles may require some experimentation. By conducting thorough wick testing and troubleshooting common issues, you can ensure that your chosen wick performs optimally and enhances the overall quality of your beeswax candle creations.

DIY wick-making for beeswax candles

Making your own custom wicks for beeswax candles is a rewarding and cost-effective way to ensure you have the perfect wick for your candles. By creating your own wicks, you have control over the materials used and can tailor them to meet your specific needs. Here is a step-by-step guide on how to make custom wicks at home for beeswax candles:

Materials Needed

– Cotton or natural fiber yarn or twine.

– Beeswax.

– Scissors.

– Ruler or tape measure.

– Pencil or pen.

Instructions

- Measure and cut the cotton or natural fiber yarn/twine to the desired length for your candle. The length will depend on the size of your container and the desired burn time.

- Place the yarn/twine in a shallow dish or tray and pour melted beeswax over it. Make sure all of the yarn is fully saturated with beeswax.

- Remove the saturated yarn from the dish, allowing any excess wax to drip off. Lay it flat on a parchment paper-lined surface to cool and harden.

- Once hardened, trim the wick to the desired length, leaving about an inch above the surface of the candle when placed in its container.

- Your custom-made wick is now ready to be used in your beeswax candle.

It’s important to note that when making your own wicks, you may need some trial and error to find the perfect thickness and stiffness that will provide an optimal burn for your specific candle size. Additionally, experimenting with different materials can also yield different results in terms of burn time and fragrance release.

Creating your own wicks not only allows you to customize them for your specific beeswax candles, but it can also be a fun and creative aspect of candle making. By following these steps and conducting thorough wick testing, you’ll be able to create candles that meet your desired burn time, fragrance release, and overall performance.

Final thoughts and conclusion

In conclusion, choosing the right wick for beeswax candles is crucial for achieving optimal burn and fragrance release. The selection of the wick directly impacts the overall quality and performance of the candle. When selecting a wick, it is important to consider factors such as candle diameter, desired burn time, and specific fragrance requirements. These factors influence the size, material, and construction of the wick.

The best wick for beeswax candles should possess certain characteristics. It should have a robust cotton or natural fiber core, proper thickness, and minimal carbon buildup. These characteristics ensure that the wick burns evenly and efficiently without producing excessive smoke or soot. By choosing a high-quality wick with these attributes, candle makers can achieve superior results in terms of burn time, fragrance throw, and overall candle aesthetics.

There are various types of wicks commonly used for beeswax candles, such as square braided, flat braided, and cotton core wicks. Each type has its own pros and cons in terms of performance and suitability for beeswax candles. Candle makers should carefully consider their specific needs before selecting a type of wick.

In conclusion, it is essential to select the best wick for beeswax candles to achieve optimal results. By experimenting with different types of wicks while considering individual goals in candle making, one can find the perfect fit that enhances the beauty and functionality of their creations.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.