Are you looking to elevate your candle making craft? Look no further than candle making molds. These essential tools play a vital role in creating the perfect shape and form for your candles.

Whether you’re a seasoned candle maker or just starting out, understanding the different types of molds and how to use them can take your creations to the next level. In this article, we will explore everything you need to know about candle making molds, from choosing the right one for your project to troubleshooting common issues. Let’s dive in and discover the endless possibilities that come with using candle making molds.

When it comes to candle making, the type of mold you use can make all the difference in achieving your desired results. From silicone and metal molds to plastic and glass options, there are various materials and shapes available that cater to different preferences and purposes. Understanding the pros and cons of each type will help you decide which mold is best suited for your specific project.

In addition to exploring the different types of candle making molds, we will also delve into tips for using these molds effectively, from pouring wax into them to releasing the finished candles without any hassle. Moreover, we will walk you through creating your very own custom mold for those who are feeling particularly creative.

So, if you’re ready to take your candle making skills up a notch, read on as we uncover everything you need to know about candle making molds.

Types of Candle Making Molds

When it comes to candle making molds, there are a variety of materials and shapes to choose from. Each type of mold offers its own unique benefits and considerations, so it’s important to understand the differences before starting your next candle making project.

One common type of candle making mold is silicone. Silicone molds are flexible, durable, and easy to clean, making them a popular choice among candle makers. They come in a wide range of shapes and sizes, allowing for endless creativity in candle designs.

Another popular material for candle making molds is metal. Metal molds are known for their durability and ability to conduct heat evenly, resulting in a smooth finish on the candles. However, they can be more challenging to clean and may require extra care when releasing the finished candles.

In addition to different materials, candle making molds also come in various shapes such as pillars, votives, tapers, and novelty shapes like hearts or stars. Each shape serves a different purpose and can add visual interest to your candles. For example, pillar molds are great for creating large, sturdy candles while votive molds are perfect for smaller container candles.

Overall, understanding the types of candle making molds available will help you make an informed decision when choosing the right mold for your specific project.

| Material | Advantages |

|---|---|

| Silicone | Flexible, durable, easy to clean |

| Metal | Durable, conducts heat evenly |

Choosing the Right Candle Making Mold for Your Project

When it comes to candle making, choosing the right mold for your project is crucial. The type of mold you use will determine the shape and size of your finished candle, as well as the ease of use during the candle making process. Here are some factors to consider when selecting a candle making mold:

- Material: Candle making molds come in a variety of materials such as silicone, metal, plastic, and glass. Each material has its own pros and cons, so it’s important to choose one that best suits your needs.

- Size and Shape: Consider the size and shape of the candle you want to create. Do you want a standard pillar candle, or do you want to get creative with unique shapes and designs?

- Durability: Depending on how often you plan to use your candle making molds, durability is an important factor to consider. Some materials may be more prone to wear and tear over time.

It’s also important to consider whether you want a reusable mold or a one-time use mold. Silicone molds are known for their flexibility and can be used multiple times, while some other materials may have a more limited lifespan.

Ultimately, the right candle making mold for your project will depend on your specific needs and preferences. Whether you’re a beginner or an experienced candle maker, there are endless options available when it comes to choosing the perfect mold for your next candle making endeavor.

Remember that using high-quality molds can greatly impact the final result of your candles. Investing in durable and well-made molds will not only make the candle-making process easier but also ensure that your finished products turn out beautifully every time.

With all these considerations in mind, take some time to explore different types of candle making molds before starting your next project. Whether you purchase ready-made molds or decide to make your own custom mold, choosing the right one will set the stage for successful candle making endeavors.

Tips for Using Candle Making Molds

When it comes to using candle making molds, there are several tips and techniques that can help ensure your candles turn out perfectly every time. One important aspect of using candle making molds is the pouring process.

It’s crucial to pour the melted wax into the mold at the right temperature to achieve a smooth and even finish. If the wax is too hot, it may create air bubbles or warp the mold, while pouring at too low a temperature might result in a rough surface on your candle.

In addition to pouring, releasing the finished candle from the mold can also be a critical step in the candle making process. To avoid damaging your candle or mold during this step, it’s essential to patiently and carefully release the candle from the mold once it has completely cooled. This may involve gently twisting or tapping the mold to loosen the candle, or using a release agent such as silicone spray to make extraction easier.

Another tip for using candle making molds is to properly prepare the mold before pouring in the wax. This may include cleaning and drying the mold thoroughly, as well as using a suitable mold sealer or release agent to prevent sticking. Taking these preparatory steps can help ensure that your finished candle comes out smoothly and retains all its intricate details if you are using decorative candle making molds.

| Tips for Using Candle Making Molds | From Pouring to Releasing |

|---|---|

| Properly prepare the mold | Before pouring in wax |

| Pour at correct temperature | For smooth finish |

| Carefully release finished candle | To avoid damage |

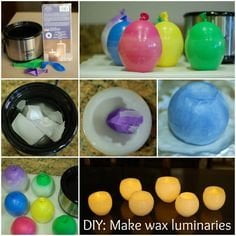

DIY Candle Making Mold

Gathering Materials and Tools

To create your own custom candle making mold, you will need a few specific materials and tools. First, you will need a container to serve as the outer shape of your mold. This can be anything from a glass jar to a plastic bottle, depending on the size and shape of the candle you want to make.

Additionally, you will need a release agent such as cooking spray or mold release spray to ensure that the finished candle can be easily removed from the mold. Finally, gather some silicone putty or hot glue to create the inner cavity of your mold.

Creating the Mold

Once you have all your materials and tools ready, it’s time to start creating your custom candle making mold. If using silicone putty, simply mix together equal parts of the two components and press it into the outer container. Make sure to create an even layer around the entire inner surface of the container. If using hot glue, carefully apply it in layers inside the container until it forms a sturdy inner cavity for your candle.

Tips for Success

When creating your own custom candle making mold, attention to detail is key. Ensure that there are no gaps or air pockets in the mold as this could affect the final shape of your candle.

Additionally, make sure to let the silicone putty or hot glue fully cure before attempting to pour wax into the mold. Once your custom mold is complete and has been properly prepared with a release agent, you can begin pouring in your melted wax to create your unique candles.

Troubleshooting Common Issues With Candle Making Molds

It’s not uncommon for candle makers to encounter issues when using candle making molds. Whether you’re a beginner or a seasoned pro, troubleshooting common problems can help ensure that your candles turn out perfect every time. Here are some tips for addressing and preventing these issues:

- Uneven Cooling: One common issue with candle making molds is uneven cooling, which can result in lumpy or misshapen candles. To prevent this, make sure your mold is placed on a flat surface and allow the candle to cool at room temperature. You can also try rotating the mold halfway through the cooling process to promote even cooling.

- Difficulty Removing the Candle: If you’re having trouble releasing the finished candle from the mold, try placing it in the freezer for a few minutes. The cold temperature can shrink the wax slightly, making it easier to pop out of the mold without causing damage. Additionally, using a mold release spray or lubricant can help prevent sticking.

- Air Bubbles: Air bubbles in your candles can be unsightly and affect their burn quality. To minimize air bubbles, try tapping the mold gently on a hard surface after pouring the wax to release any trapped air. You can also try pouring the wax at a slightly higher temperature to help minimize air entrapment.

Troubleshooting common issues with candle making molds is an essential part of the candle-making process. By identifying and addressing these problems, you can create high-quality candles that meet your standards.

Remember these key points:

- Ensure even cooling of your candles by placing your mold on a flat surface and rotating it during the cooling process.

- To release stubborn candles from their molds, use the freezing method or invest in a good mold release spray.

- To minimize air bubbles in your candles, tap the mold gently after pouring or adjust your pouring temperature.

By incorporating these troubleshooting tips into your candle making routine, you’ll be better equipped to handle any issues that may arise with your candle making molds.

Creative Ways to Use Candle Making Molds

Candle making molds are not just limited to creating traditional candles. There are numerous creative ways to use these molds to make unique and innovative products that can enhance the ambiance of any space. From wax melts to decorative items, here are some creative ways to use candle making molds beyond traditional candles.

Wax Melts

One popular alternative use for candle making molds is to create wax melts. Wax melts are small, scented pieces of wax that can be melted in a warmer to release fragrance into the air. They are perfect for those who want to enjoy the aroma of a candle without an open flame. Using various shapes and sizes of candle making molds, you can create your own custom wax melts in different scents and colors to suit your preferences.

Decorative Soaps

Another creative way to use candle making molds is for crafting decorative soaps. With the right materials and techniques, you can easily repurpose your candle making molds to create beautifully shaped soaps. Whether you prefer floral designs or geometric shapes, the possibilities are endless when it comes to using candle making molds for soap making.

Beeswax Wraps

Candle making molds can also be used to make beeswax wraps, which are eco-friendly alternatives to plastic wrap for food storage. By pouring melted beeswax into the molds and allowing it to set, you can create reusable and sustainable wraps that can be used to cover bowls, wrap sandwiches, or preserve fruits and vegetables. This is a great way to reduce single-use plastic in your home while getting creative with your candle making molds.

By exploring these creative uses for candle making molds, you can unleash your imagination and transform simple materials into unique and practical products. The versatility of candle making molds allows for endless possibilities beyond traditional candles, providing an exciting outlet for crafters and artisans alike.

Maintaining and Cleaning Candle Making Molds for Longevity and Reuse

In conclusion, maintaining and cleaning candle making molds is essential for their longevity and reuse. Taking care of your molds will ensure that they continue to produce high-quality candles for many more projects to come. By following proper maintenance and cleaning practices, you can save money on buying new molds and also reduce waste in the environment.

Regularly inspecting your candle making molds for any damage or wear and tear is the first step in maintaining their longevity. Small cracks or deformities can affect the quality of your finished candles, so it’s important to address these issues as soon as possible. Additionally, cleaning your molds after each use will prevent any residue from building up and affecting the shape and smoothness of your candles.

When it comes to cleaning candle making molds, using mild soap and warm water is usually sufficient for most materials. However, for more stubborn residues, you can also try vinegar or baking soda solutions. It’s important to thoroughly dry the molds before storing them to prevent any mold or mildew growth. Proper storage in a cool, dry place will further extend the life of your molds.

By taking the time to maintain and clean your candle making molds, you can ensure that they remain in excellent condition for future use. Whether you are using pre-made molds or creating your own custom designs, proper care of your molds will result in beautiful candles every time. With a little effort in upkeep, your candle making molds can continue to be a valuable tool in your crafting endeavors.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.