Accurate wax measurements play a crucial role in achieving consistent candle quality and performance. In the world of candle making, precision is key, as even a slight deviation in wax measurements can drastically affect the outcome of the finished product. Not only does properly measuring wax ensure that candles burn evenly and efficiently, but it also contributes to the overall safety of the candle making process.

When it comes to candle making, there are various types of waxes to choose from, each with its own unique properties and characteristics. Whether you’re using soy wax, paraffin wax, or beeswax, understanding how to measure each type accurately is essential. Different types of wax may require different techniques for measuring, as their densities and melting points can vary significantly.

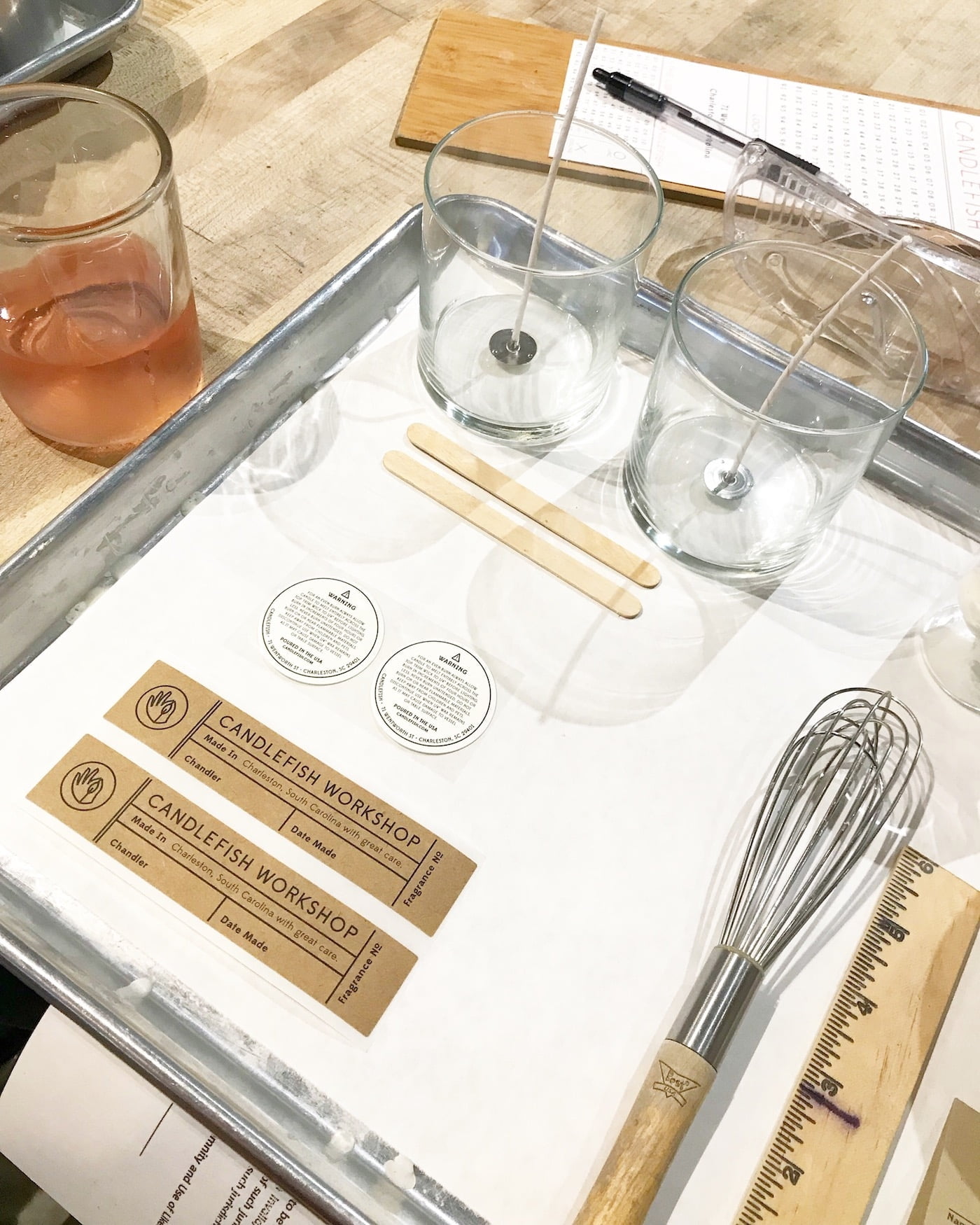

To measure wax accurately, it’s important to arm yourself with the right tools. Various tools such as scales, thermometers, and measuring cups are necessary for precise measurements. Each tool has a specific purpose and knowing how to use them effectively will ensure that your measurements are consistent every time. Choosing the appropriate tools based on the scaling and types of wax being used is equally important.

Mastering wax measurements in candle making is a skill that every enthusiast should strive for. It not only elevates your craft but also enables you to troubleshoot common issues that may arise due to incorrect measurements. By understanding the importance of proper wax measurements and implementing accurate techniques from start to finish, you can enhance your candle making skills and create beautiful candles consistently.

Exploring Different Types of Candle Making Wax

Candle making involves a variety of waxes that contribute to the overall quality and performance of the final product. Understanding the different types of waxes available is essential for candle makers to achieve their desired results.

One commonly used wax is soy wax, which is derived from soybean oil. Soy wax has gained popularity in recent years due to its natural and renewable nature. It also has a lower melting point, allowing for longer burning times and better scent throw. Soy wax is known for its clean burn and excellent fragrance retention.

Another widely used wax is paraffin wax, which has been a staple in candle making for many years. Paraffin wax is derived from petroleum and offers versatility in terms of color options and fragrance absorption. It has a higher melting point compared to soy wax, resulting in stronger scents but may produce more soot when burned.

Beeswax, on the other hand, is a natural byproduct made by honey bees. It has a distinctive sweet smell and produces a warm and soft glow when burned. Beeswax candles have excellent burn times and purify the air as they release negative ions into the environment. However, beeswax can be costly compared to other waxes.

When working with different types of waxes, it’s important to consider their specific properties and characteristics. Each type may require specific techniques or considerations when measuring. For example, soy wax may require slightly higher measurements than paraffin wax due to its lower density. Being aware of these differences will help candle makers create candles with consistent quality and performance.

Table: Comparing Different Types of Candle Making Wax

| Types of Wax | Properties | Characteristics |

|---|---|---|

| Soy Wax | Derived from soybean oil | Natural, renewable, lower melting point, clean burn, excellent fragrance retention |

| Paraffin Wax | Derived from petroleum | Versatile color options, strong scent throw, may produce more soot |

| Beeswax | Natural byproduct made by honey bees | Purifies the air, warm glow when burned, can be costly |

Essential Tools for Measuring Candle Making Wax

Accurate wax measurements are crucial in achieving consistent candle quality and performance. To ensure precision, it is essential to have the right tools for measuring candle making wax. These tools not only aid in obtaining the correct amount of wax but also contribute to safety during the candle-making process.

The following is a comprehensive list of tools needed for measuring wax accurately:

1. Digital Scale: A digital scale is an invaluable tool for measuring wax by weight. It provides precise measurements and allows for consistency in candle making. When using a digital scale, make sure it has a high enough capacity to accommodate the weight of your desired wax quantity.

2. Thermometer: A thermometer is necessary to monitor the temperature of the wax during melting and pouring. Different types of waxes have specific melting points, so it is crucial to follow the manufacturer’s guidelines. Using a thermometer ensures that you pour the melted wax at the optimum temperature for optimal results.

3. Measuring Cup or Container: A heat-resistant measuring cup or container with clear markings will help measure wax volume accurately. Look for one that can withstand high temperatures and has clear graduations, allowing you to read the measurements easily.

4. Wax Melting Pot: A dedicated pot specifically designed for melting candle making wax helps prevent contamination between different types of waxes or fragrance oils used in different candles. Choose a pot with a pouring spout and a handle for easy pouring without spills.

5. Stirring Utensil: A long-handled spoon or spatula made from heat-resistant materials like silicone or stainless steel is necessary to stir the melting wax, ensuring even distribution of heat and maximizing fragrance blending if adding scent oils or color additives.

When choosing these tools, consider factors such as their durability, accuracy, ease of use, and compatibility with your preferred scaling method (weight or volume). Investing in high-quality tools will not only result in better measurement accuracy but also enhance your overall candle-making experience.

In the next section, we will explore how to establish correct wax measurements for different candle sizes and shapes, taking into account the desired amount of wax needed for specific molds or containers.

Establishing Correct Wax Measurements for Different Candle Sizes and Shapes

The Importance of Adjusting Wax Measurements

When it comes to candle making, achieving the desired size and shape of candles is essential. This not only contributes to the aesthetic appeal but also affects the candle’s burn time and overall performance. It is crucial to establish correct wax measurements based on the specific candle size and shape you want to create. By doing so, you can ensure optimal results and avoid common issues such as uneven burning or poor scent throw.

Determining the Appropriate Amount of Wax

To establish correct wax measurements for different candle sizes and shapes, a step-by-step approach can be followed. First, determine the type of mold or container you will be using for your candle. Each mold or container will have a different capacity, requiring a specific amount of wax to fill it adequately.

Start by measuring the dimensions of your desired candle mold or container – height, width, and depth. Using these measurements, calculate the volume of wax needed using a formula or conversion table specifically designed for this purpose. Remember that certain types of waxes might require adjustments in measurements due to variations in density or melting properties.

Converting Wax Measurements

In some cases, you may find yourself wanting to make candles in varying sizes using a single recipe. To achieve this, it is helpful to have a conversion table that allows you to easily adapt your wax measurements from one size to another. By inputting the original measurements and desired new size into the conversion table, you can quickly determine the adjusted amount of wax needed for each component.

By establishing correct wax measurements for different candle sizes and shapes, you can ensure consistent results across your entire candle-making process. Proper measurement techniques are integral in creating candles that burn evenly, emit fragrance effectively, and maintain their desired appearance throughout their lifespan.

Ensuring Precision

Measuring wax accurately is essential in achieving consistent candle quality and performance. One important consideration when measuring wax is whether to use weight or volume as the measurement unit. Each method has its pros and cons, and it is crucial to understand the significance of using the right approach for precise measurements.

Measuring wax by weight involves using a digital scale to determine the exact weight of the wax needed. This method provides precise measurements, ensuring consistency in candle-making. Using a scale also allows for easy adjustments if a recipe needs to be scaled up or down. Additionally, measuring by weight is particularly useful when working with different types of waxes that may have distinct densities.

On the other hand, measuring wax by volume involves calculating the amount of space a specific quantity of wax occupies. This method uses volumetric tools such as graduated cylinders or measuring cups. Measuring by volume can be convenient for beginners who may not have access to a digital scale. However, it is important to note that measuring by volume may not be as accurate as weighing since factors such as air bubbles or irregular shapes can affect the measurement.

To ensure precision when measuring wax, it is crucial to use consistent techniques regardless of whether you choose weight or volume measurements. This means using the same tools and following standardized methods each time you measure wax for candle making. It is also recommended to calibrate your tools regularly to maintain accuracy.

| Method | Pros | Cons |

|---|---|---|

| Measuring by Weight | – Precise and accurate measurements – Easy for recipe scaling. – Suitable for different wax types and densities | – Requires a digital scale – May not be accessible for beginners |

| Measuring by Volume | – Convenient, especially for beginners – Can yield satisfactory results. – No need for a digital scale | – Less accurate than weight measurements – Prone to factors like air bubbles or irregular shapes affecting measurement |

Common Mistakes to Avoid When Measuring Candle Making Wax

Measuring candle making wax accurately is crucial for achieving consistent candle quality and performance. However, there are common mistakes that beginners may make when measuring wax that can lead to disappointing results. By avoiding these mistakes, you can improve measurement accuracy and elevate your candle making skills.

- Eyeballing Measurements: One of the most common mistakes is eyeballing wax measurements instead of using precise tools. It may be tempting to estimate the amount of wax needed, but this can result in inconsistent candle sizes and burning times. To avoid this mistake, always use proper tools such as a scale or measuring cup to ensure accurate measurements.

- Neglecting Temperature Changes: Wax measurements can be affected by temperature changes, especially if you measure by volume. As the wax cools or heats up, its density can change, leading to inaccurate measurements. To avoid this mistake, always measure wax at a consistent temperature or consider using weight measurements instead.

- Ignoring Shrinkage: Many beginners overlook the shrinkage that occurs during the cooling process of candles. This often leads to overpouring the wax into molds or containers, resulting in overflow or misshapen candles. To avoid this mistake, take into account the expected shrinkage rate and adjust your measurements accordingly.

To improve your measurement accuracy in candle making, it’s important to invest in the right tools and techniques. Here are some tips:

– Use a digital scale for precise weight measurements.

– If measuring by volume, choose a reliable measuring cup with clear markings.

– Consider using a thermometer to monitor and maintain consistent temperatures during the melting and pouring process.

– Be mindful of any additives or fragrances being used that may impact your measurements (refer to Section 7 for more information).

By avoiding common mistakes and implementing proper measurement techniques in your candle making process, you can achieve more consistent results and elevate your skills as a candle maker.

Measuring Fragrance and Color Additives in Candle Making Wax

Adding fragrance and color additives to candle making wax can greatly enhance the final product. However, it is essential to measure these additives accurately in order to achieve the desired scent throw and color intensity. This section will provide guidance on how to measure fragrance and color additives effectively.

When measuring fragrance oils for candle making, it is important to follow the manufacturer’s recommended usage rate. Typically, fragrance oils are measured by weight using a digital scale. Use a separate container for weighing fragrance oils to avoid contaminating the main batch of wax. It is also important to note that different fragrances have different weights, so a conversion chart may be helpful when working with various scents.

Color additives, such as liquid dyes or color blocks, can also enhance the appearance of candles. Measuring these additives accurately ensures consistent color throughout the candle. Liquid dyes are often measured by volume using droppers or pipettes. Remember to use separate droppers for each color to prevent cross-contamination.

If using color blocks, they can be measured by weight or volume, depending on personal preference and ease of use. When measuring by weight, cut off a small piece of the block and weigh it on a digital scale. For volume measurement, dissolve a small piece of the block in a known amount of liquid wax and determine the ratio required for desired color intensity.

When incorporating fragrance and color additives into the wax, start with smaller amounts and gradually increase until reaching the desired strength or shade. Keep in mind that some fragrances may react differently in combination with certain colors, so experimentation may be necessary.

By taking accurate measurements of fragrance and color additives in candle making wax, you can ensure consistent results and create beautiful candles that delight your senses visually and aromatically.

Troubleshooting Wax Measurements

When it comes to candle making, one of the most crucial aspects is getting the wax measurements right. Incorrect measurements can lead to a range of problems, including uneven burning, poor scent throw, and color inconsistency. In this section, we will explore some common issues that arise due to incorrect wax measurements and provide troubleshooting techniques to overcome them.

Uneven Burning

One common issue that candle makers may encounter is uneven burning. This happens when there is an imbalance between the wick size and the amount of wax in the container or mold. If there is too much wax in proportion to the wick size, it can cause the candle to burn unevenly, with excess wax pooling around the wick.

To troubleshoot this problem, you can start by adjusting your wax measurement. Make sure you are using the recommended amount of wax for your specific container size or mold. Additionally, check if your wick size is appropriate for the amount of wax being used. Sometimes using a larger wick can help distribute heat more evenly across the surface area of the candle.

Poor Scent Throw

Another common issue faced by candle makers is poor scent throw, where the fragrance of a candle is not as strong as desired when burned. This can be attributed to improper measurement of fragrance oils or not using enough oil for a particular quantity of wax.

To address this problem, ensure that you are accurately measuring your fragrance oils according to the recommended guidelines provided by suppliers or recipe guides. It’s essential not to exceed or skimp on recommended amounts as it can affect both performance and safety of your candles. Experimenting with different quantities may be necessary until you find an optimal balance that produces desired scent intensity.

Color Inconsistency

Achieving consistent color throughout a batch of candles can also be challenging if proper measurements are not followed. Color inconsistency might occur if color additives are not measured accurately or if they are not thoroughly mixed into the wax.

To overcome this issue, ensure that color additives are properly measured using reliable instruments such as measuring spoons or droppers. Follow the recommended guidelines for each specific color additive to achieve consistent results. Additionally, make sure to mix the wax and color additives thoroughly before pouring them into the molds or containers. This will help distribute the color uniformly throughout the candle and prevent any streaking or patchiness.

By addressing these common issues related to wax measurements, you can enhance the quality and performance of your candles. Troubleshooting candle making problems requires patience and experimentation, but with practice and attention to detail, you can refine your techniques and create beautiful candles every time.

Conclusion

In conclusion, mastering wax measurements is a critical skill that can greatly elevate your candle making abilities. Throughout this article, we have emphasized the importance of precise wax measurements in achieving consistent candle quality and performance. Accurate measurements not only ensure that you produce candles that burn evenly and safely but also allow you to create candles of various sizes and shapes with ease.

By exploring different types of candle making waxes, you have gained knowledge about their specific properties and characteristics. This understanding will help you determine the appropriate measuring techniques for each type of wax, guaranteeing accurate results. Additionally, we provided a comprehensive list of essential tools for measuring wax accurately, allowing you to choose the right tools based on the scaling and types of wax being used.

Establishing correct wax measurements for different candle sizes and shapes is paramount in producing candles that meet your desired specifications. We have provided step-by-step instructions for determining the appropriate amount of wax required for various molds or containers, along with conversion tables or formulas to assist you in adjusting quantities as needed.

Furthermore, we discussed the pros and cons of measuring wax by weight versus volume, emphasizing the significance of using a digital scale for precise weight measurements. Regardless of which method you choose, consistency in your measuring techniques is key to achieving consistent results.

Avoiding common mistakes when measuring candle making wax is crucial for improving measurement accuracy. By following our practical tips and sharing personal experiences or stories, we hope to make this topic relatable and engaging. Ultimately, through trial and error and continuous practice, you can refine your skills and avoid potential pitfalls.

Lastly, we addressed the additional considerations when measuring fragrance oils and color additives in candle making wax. Proper calculations are necessary to achieve the desired scent throw and color intensity in your candles. By providing tips on accurately measuring and incorporating additives into your wax, we aim to help you enhance the overall aesthetic appeal of your candles.

In conclusion, mastering wax measurements is an ongoing journey that will elevate your candle making skills to new heights. With consistent practice and attention to detail, you can achieve candles of exceptional quality that burn evenly, smell divine, and delight your customers or loved ones. Remember, precision in wax measurements is the foundation of excellence in candle making. So keep learning, experimenting, and refining your techniques to create candles that showcase your creativity and craftsmanship.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.