Introduction

Cleaning candle making equipment is an essential part of the candle making process to ensure its safety and efficacy. Not only it helps with professional-grade results, but also prevents contamination and health risks associated with candle making. It is also important to maintain hygiene when working with wax and wicks. Proper cleaning of the utensils will not only promote a long lasting scent of the finished product, but also enhance your reputation as a professional candle maker.

It is important to clean all candle making supplies between uses to prevent cross contamination between batches. As soon as you finish working with a certain ingredient, be sure to rinse and dry the equipment thoroughly before adding any other ingredients to the equation. This includes materials like wax, wicks, containers, molds and pots, scents or additives, thermometers, colorants and more. Even after every use it’s critical that one cleans their tools while they are still warm because wax can easily become harden if allowed too cool down.

Along with using soap and water for general cleaning of all surfaces, additional steps may be necessary for some materials depending on usage time or type of residue left behind on tools or utensils. For large pieces of equipment like wick holders or melting pots, hot water can be used for removing stubborn wax stains along with mild abrasives like baking soda or BBQ grill cleaner. Nail polish remover may be useful for dealing with colorants leftover on containers or molds as well as reacting stove top drip pans where melted wax has spilled onto them. With proper cleaning and maintenance implemented consistently one can prolong the life of candle making supplies while avoiding contaminations in their creations.

Candle Making Basics

Cleaning the Equipment– Ensuring your candle making equipment is clean and properly sanitized is important. To do this, start by wiping down all of the surfaces to remove any dirt or wax residue. Using soapy warm water with a drop of bleach can help to thoroughly disinfect surfaces, however if you are using mold or jars wipe only with soapy water. For metal wicks, use a damp cloth soaked in boiling water to quickly break down any wax build-up. You can also boil your wick pins and wick tabs before use—just make sure to dry them off completely before adding the wicks. Any tools that have come into contact with hot wax or dye should be wiped clean with a wet cloth and either stored for future use or disposed of in an appropriate manner, such as recycling. Finally, make sure you store your supplies and tools in an area that’s cool, dry and away from direct sunlight to prevent them from becoming damaged over time.

Make Cleaning Part of Your Candle Making Routine

It is important to make cleaning part of your candle-making routine. Candles may seem like fairly simple things, but the process of making them (especially as a business) can be complex and results in all sorts of melted wax, wicks, oils, dyes and glitters that need to be contained and, eventually, cleaned up. To ensure all steps necessary for professional-grade, safe candles are met, a clean working space is essential. This means taking the time to fully clean each tool before and after each use.

It is important not to rush through this process or it can lead to greater messes or potentially dangerous conditions if leftover material isn’t disposed of properly. Start by wiping the equipment down with a paper towel and rubbing alcohol after every use; this will help prevent any buildup from occurring in the nooks and crannies of tools you use regularly. Then thoroughly wash any plastic pieces by hand with warm soapy water, being sure to rinse away residue completely. The same goes for glass items such as measuring cups or mixing bowls; but instead of putting into an automatic dishwasher you should use protective gloves when cleaning these because the wax does not break down easily like regular grease does in most washers. Finally, make sure that all chemicals used have been put away securely which includes double-bagging oversized containers in a wrapped trash bag for extra protection before disposal or disposal offsite if necessary when required – since some waxes cannot go into standard sewage systems without specific handling procedures!

Detailed Guide to Cleaning Burning Equipment

When cleaning candle making equipment such as wicks, mold inserts, and melting pots, it is important to take extra care to ensure both effective cleaning, as well as safety. Incorrectly cleaned equipment can result in a poor burning experience for your candles and can even be dangerous. Here is a step-by-step guide to properly clean each specific type of candle making equipment.

For wicks: To ensure proper cleaning, start by soaking the wick in a mixture of warm water and vinegar for fifteen minutes. Make sure you change the mixture often so that it doesn’t become too saturated with wax residue. Afterward, gently scrub any wax residue off with a soft cloth and allow it to dry before burning your next batch of candles.

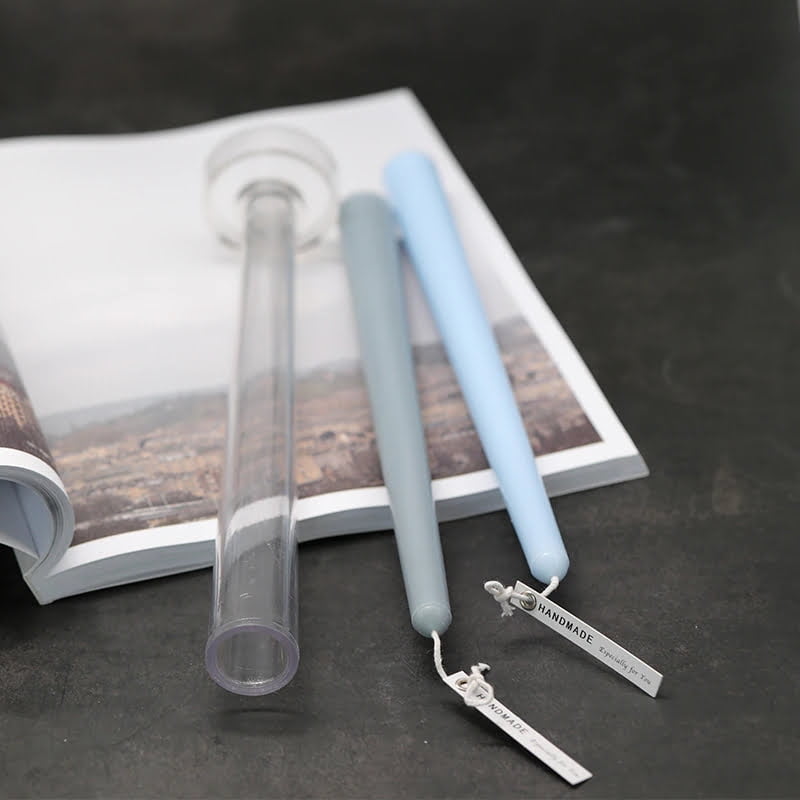

For mold inserts: After pouring each wax mixture into the mold insert, use a paper towel or damp cloth to lightly rub away any sticking wax residue and then set aside until the next batch of candles is ready to be poured. If there are excess streaks or tough areas that won’t come off easily with just a cloth or paper towel, use cotton swabs to carefully remove them Finally, give the entire molds a quick wipe down with vinegar water before using them again for future batches of candles.

For melting pots: Since many metal melting pots contain traces of contaminants left over from previous batches of candles, it is important to properly clean them before starting new batches of wax melts. Start by filling it up with hot water and detergent and let sit for 10 minutes (be sure not to use boiling water). Afterward, use some paper towels or a soft brush dipped in vinegar water for tougher areas on your pot’s surface before wiping down completely dry with another soft cloth. Finally rinse out all remaining soap residue in hot running water until clean before storing away until needed again.

Tips for Melting Equipment Care and Cleaning

In order to keep your candle making equipment in good condition, it’s important to properly clean and maintain it. Here are some tips for caring for your melting equipment:

• Allow wax from the same scent family to cool before switching fragrances. This will help prevent any accidental cross-contamination.

• Before each use, make sure to wipe down any surfaces that were exposed to wax with an appropriate cleaner or degreaser such as mineral spirits or denatured alcohol.

• Always ensure pot and other components are completely dry before filling with wax again. This helps reduce chances of a fire or contamination due to moisture being added during the pouring process.

• Regularly inspect heating elements and wiring on double boiler systems for signs of wear or damage and replace damaged parts promptly as needed

• Clean wick holders between uses with warm, soapy water and then dry them thoroughly

thermometers—follow manufacturer instructions for care, cleaning and storage instructions.

• Be sure to wipe all tools you use while making candles, such as stirring sticks and tools used for measuring fragrance or dye chips into the wax, before storing them away.

• Take regular care of all your melters by periodically replacing hoses, gaskets and other components from time to time according to manufacturer specifications.

Keep Your Storage Areas Organized and Clean for Maximum Efficiency

Storage areas should be regularly cleaned and organized to ensure maximum efficiency when it comes to candle making. All tools, ingredients, and equipment should be properly sorted to make knowing what supplies you have on hand a breeze and prevent cross-contamination of items. Utensils, tables, shelves, and any other surfaces used throughout the candle-making process need to be wiped down with an appropriate cleaner after every use; this will help prevent the build-up of waxes, residue, oils and other materials that can impact future projects. Additionally, tools should be inspected for any wear or damage before being used each time in order to avoid any safety hazards or fire risks. Be sure to also store materials away from heat and moisture sources so they don’t become damaged and unusable. Lastly, candles should be kept in airtight containers until ready to be used; this will help preserve their freshness while preventing dust from collecting on them. By maintaining a clean workspace with the proper protocols in place, candle makers can maximize their productivity without compromising the quality of their craft.

Cleaning Tips for Pouring Equipment Maintenance

Cleaning candle making equipment can be essential to maintaining the safety and quality of your candles. Whether you are just starting out or have been in the business for years, it’s important to take proper care of your tools and pouring equipment. Here are some easy tips for maintaining your supplies:

1. Make sure to wash off any wax or soot residue from your melters or table tops after use to prevent build-up. You can use a non-abrasive cloth dampened with warm soapy water or mineral spirits for a thorough clean-up.

2. For wick pins and tab holders, use hot soapy water to get rid of any residues that might interfere with the burning process. Don’t forget to unplug all electrical components before cleaning them!

3. After each use, make sure to clean thermometers, containers (if they come in contact with hot wax), dippers and funnels used while pouring candle wax into molds. To ensure these items don’t retain heat, place them in cold water immediately after use and give them a quick scrub before drying them neatly and storing away properly.

4. Pots and pans that are used in melting wax must also be carefully cleaned out any molten material left behind standing between uses in order to avoid damaging the equipment or fire hazards occurring over time due to wax build up on these materials due to fat layers present in certain products such as coconut oil weather solid at room temperature or not . Heat resistant spatulas should also be used with care when scraping away residue in order not too scratch metal surfaces .

5. Regularly check for broken wicks, metal contamination in cans/containers being used repeatedly as well as moulds that don’t form correctly etc., this will prevent disruption during production runs on a larger scale which could delay an entire batch run if not caught early enough and more than one container/candle badly affected by issues still present despite sitting overnight until fully cured .

Best Practices for Recycling and Disposing of Candle Making Equipment

It is important to practice safety and proper cleaning techniques when dealing with candle making equipment. Before every use, it is important to check for any signs of damage or wear and tear on any equipment as even the smallest imperfections can result in a negative reaction during the candle making process. Wicks and other fabric accessories should be removed from hot wax prior to disposing of it through appropriate waste management facilities, such as the local sanitation department.

When recycling used candle making equipment, it is important to thoroughly wash it in warm, soapy water with a soft-bristled brush and rinse with clear water. This will help remove any leftover wax particles that can attract dust and bacteria. After washing each piece of equipment, air dry all components before storing them in a cool, dry place away from extreme temperatures or moisture. Finally, rinse out any containers that held dripping wax with hot water and allow them to fully dry before re-purposing them for other uses.

Celebrate a Clean Candle Making Environment

Celebrating a clean candle making environment isn’t just a matter of keeping your tools and supplies neat and tidy. It also involves taking the necessary steps to sanitize all of your equipment regularly. This can help protect against the growth of bacteria or mold, which can make your candles look unattractive, or worse – dangerous to use. To make sure you have a clean and safe candle making setup, follow these simple steps:

1. Start by wiping down all of your equipment with a soft cloth and hot soapy water. This will help remove any wax build-up on the surfaces of the items and keep them looking better for longer.

2. Once wiped down, it is recommended that you rinse all items thoroughly with warm water to ensure any soap residue has been eliminated from the surface.

3. To get rid of germs, use an alcohol-based cleaner such as rubbing alcohol and sterilize each tool or piece of equipment individually before drying off with a lint-free cloth.

4. If burning candles in an enclosed space or area, always use an air purifier to reduce odors caused by smoke or heat damage from the candle flame itself. This will help prevent potential respiratory issues due to inhalation over long periods of time.

5. Replace any old wicks, containers or other candle supply items that may have become easily damaged by heat or fire over time – this includes purchasing new wicks if they look like they’ve been used extensively in one batch of candles as they often do not burn uniformally after being used many times in different batches

Conclusion

Once you have finished making your candles, you will want to make sure that all of your candle making equipment is thoroughly cleaned. Start by wiping down any surfaces with a wet rag or paper towel and soap and water. If there are any hard to reach places or difficult spots, use a brush and some dishwashing liquid. Scrub away the excess wax and ensure that all the wicks are removed from the molds before washing. Make sure to use warm water when cleaning items like thermometers and scales so that they can be easily sanitized. When everything is dry, store your candle making supplies in airtight containers until they are ready to be used again.

When it comes to candle making, taking the extra time to properly clean your materials helps ensure that you create beautiful eco-friendly candles with a shine that lasts. Not only does this allow you to maintain a sterling reputation for hand-crafted candles but it also proves that you care about protecting our environment! Whether you are creating basic tapers or intricate sculptures, taking care of your supplies does not have to be onerous task if done routinely – just remember to wipe surfaces down after each use for best results!

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.