Are you wondering how to filter beeswax for candle making? Beeswax is a popular choice for candle making due to its natural, sweet aroma and clean-burning properties. However, raw beeswax contains impurities that can affect the quality and appearance of your candles. In this article, we will explore the importance of filtering beeswax in candle making and provide a step-by-step guide on how to achieve the best filtration results.

When it comes to candle making, the quality of the beeswax used plays a crucial role in determining the final outcome of your candles. Unfiltered beeswax contains various impurities such as debris, pollen, and remnants of honeycomb that can affect the scent, color, and texture of your candles. Filtering beeswax not only removes these impurities but also ensures a smoother and more consistent burning experience for your candles.

To filter beeswax effectively, it is essential to understand the different impurities found in raw beeswax and why they need to be filtered out. Additionally, knowing the necessary equipment and materials needed for filtering beeswax is crucial for achieving optimal results. In the following sections, we will delve into these topics and provide valuable insights into the various filtration methods available for your specific candle making needs.

The Various Impurities Found in Raw Beeswax and Why They Need to Be Filtered Out

When working with raw beeswax for candle making, it is crucial to understand the various impurities that can be found in the wax and why they need to be filtered out before use. Raw beeswax can contain debris, propolis, pollen, and other organic materials that can affect the quality and appearance of your candles if not properly removed through filtration.

Here are some of the common impurities found in raw beeswax:

- Debris: This can include small particles of wood, bee wings, or dirt that may have been collected during the honey extraction process.

- Propolis: A resin-like substance collected by bees from tree buds and used as a sealant in the hive. While propolis has its own beneficial properties, it can create specks or sediment in your candles if not filtered out.

- Pollen: Beeswax can contain traces of pollen which, if left unfiltered, can create dark specks in your candles.

These impurities need to be filtered out of the beeswax to ensure a clean and smooth burn when used in candle making. Failure to filter out these impurities can result in poor-quality candles with an uneven texture and appearance.

To properly filter beeswax for candle making purposes, consider using the following equipment and materials:

- Double boiler or melter

- Cheesecloth or fine mesh strainer

- Coffee filters or specialized wax filtering equipment

- Heat-resistant gloves

By using these basic materials and following specific steps on how to filter beeswax for candle making, you can achieve smooth, high-quality wax ready for creating beautiful candles for personal use or sale. Remember that proper filtration is key to achieving favorable results and ensuring customer satisfaction with your products.

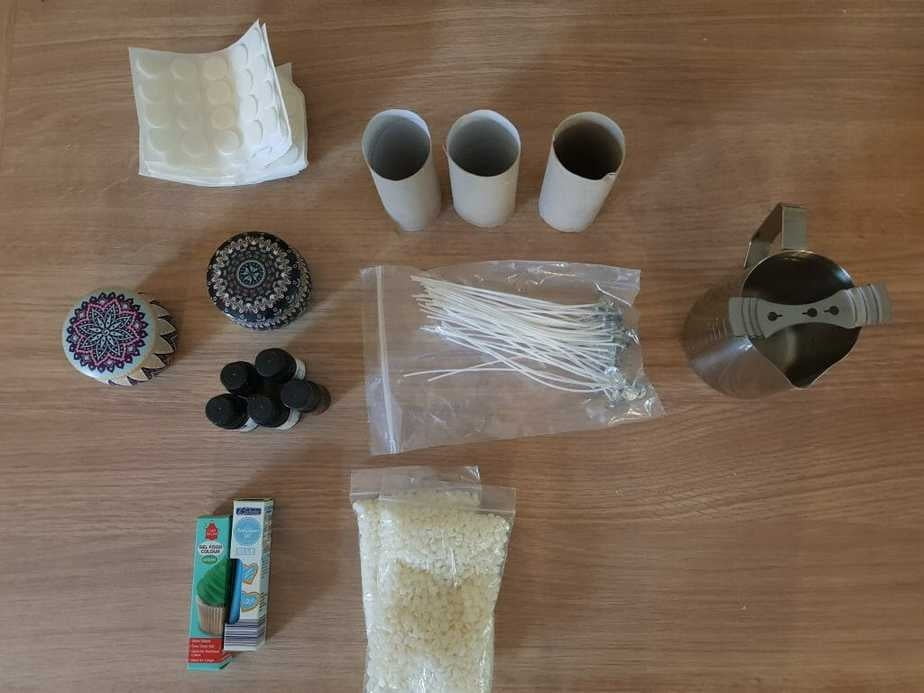

Necessary Equipment and Materials Needed for Filtering Beeswax

When it comes to filtering beeswax for candle making, having the right equipment and materials is crucial to achieve the best results. The main goal of filtering beeswax is to remove impurities and debris, leaving you with clean and pure beeswax for your candles. To effectively filter beeswax, you will need some essential equipment and materials.

One of the key items you’ll need is a double boiler or a large metal pot and a smaller one that fits inside it. This setup allows you to melt the beeswax gently without direct heat, reducing the risk of scorching or burning the wax. Additionally, having a thermometer on hand is important to monitor the temperature of the melted beeswax, as overheating can affect its quality.

Another vital piece of equipment is a fine mesh strainer or cheesecloth. This will be used to strain out any solid impurities from the melted beeswax as it passes through, ensuring that your filtered wax is free from debris. It’s also recommended to have a large stainless steel spoon or ladle for stirring and transferring the wax during the filtration process.

In terms of materials, make sure you have plenty of disposable paper towels or coffee filters for pre-filtering the raw beeswax before it goes through the final filtration process. These materials will help remove larger particles and sediment from the beeswax before it reaches the strainer or cheesecloth. When preparing to filter your beeswax, having these necessary equipment and materials on hand will help ensure that your candle making process runs smoothly and efficiently.

Step by Step Guide on How to Filter Beeswax for Candle Making

There are various impurities found in raw beeswax, such as debris, pollen, and other contaminants that can affect the quality and appearance of the candles. Filtering beeswax is an essential step in the candle making process to ensure that these impurities are removed, resulting in a cleaner and more refined final product. By filtering beeswax, you can improve the burn time, scent throw, and overall aesthetic of your candles.

To filter beeswax for candle making, you will need a few essential pieces of equipment and materials. First and foremost, you will need raw beeswax, a heat source such as a double boiler or crockpot, cheesecloth or a fine mesh strainer, and heat-safe containers for melting and filtering the wax. It’s important to dedicate specific equipment solely for beeswax filtration to prevent any cross-contamination with food items.

Once you have gathered all the necessary equipment and materials, you can begin the process of filtering beeswax for candle making. One method involves melting the raw beeswax in a double boiler or crockpot until it becomes completely liquefied. After melting the wax, it should be strained through a fine mesh strainer or several layers of cheesecloth to remove any impurities. This process may need to be repeated multiple times to achieve the desired level of filtration.

| Equipment | Materials |

|---|---|

| Double boiler or crockpot | Raw Beeswax |

| Cheesecloth or Fine Mesh Strainer | |

| Heat-safe containers |

Tips and Tricks for Achieving the Best Filtration Results

Filtering beeswax for candle making can be a delicate process, but with the right tips and tricks, you can achieve the best filtration results. Here are a few key pointers to keep in mind when filtering beeswax for candle making.

Use High-Quality Filtering Materials

One of the most important factors in achieving the best filtration results is using high-quality filtering materials. This includes using fine mesh filters, cheesecloth, or specialized wax filters designed specifically for beeswax filtration. These materials will help to capture even the smallest impurities and ensure that your beeswax is thoroughly filtered before use in candle making.

Filter Multiple Times

To achieve the cleanest beeswax possible, it’s often necessary to filter the wax multiple times. After your initial filtration process, allow the beeswax to cool and then repeat the filtering process. This will help to catch any remaining impurities that may have been missed during the first round of filtration.

Avoid Overheating

When filtering beeswax, it’s important to avoid overheating the wax. Excessive heat can cause the wax to discolor or lose its natural fragrance. To prevent this, use a low heat setting when melting the wax for filtration and avoid prolonged exposure to heat.

By keeping these tips and tricks in mind, you can achieve excellent filtration results when working with beeswax for candle making.

Common Mistakes to Avoid When Filtering Beeswax

When it comes to filtering beeswax for candle making, there are some common mistakes that beginners often make. Avoiding these mistakes can ensure that your candles turn out with the best quality and appearance. Here are some key mistakes to watch out for:

- Not using the right equipment: Using the wrong type of filter or not having proper equipment can result in inefficient filtration. It’s important to invest in a good quality filter and other necessary tools to ensure that the beeswax is properly filtered.

- Skipping the pre-filtering process: One mistake that many novice candle makers make is skipping the pre-filtering process. Pre-filtering helps remove larger debris and impurities, making the final filtration process much more effective.

- Overheating the beeswax: Overheating the beeswax during the filtration process can cause it to lose its natural properties and affect the quality of your candles. It’s important to keep a close eye on the temperature and avoid overheating at all costs.

In order to achieve the best results when filtering beeswax for candle making, it’s crucial to be mindful of these common mistakes. By using the right equipment, following proper filtering processes, and maintaining careful temperature control, you can ensure that your candles are of the highest quality.

Remember, taking the time to filter beeswax properly will have a significant impact on the overall appearance and burn quality of your candles.

Different Filtration Methods and Which One Is Best for Your Specific Candle Making Needs

When it comes to filtering beeswax for candle making, there are several different methods that can be used. Each method has its own unique benefits and drawbacks, so it’s important to understand which one is best for your specific candle making needs. One common method of filtering beeswax is using a cheesecloth or muslin cloth. This method involves pouring the melted beeswax through the cloth, which will catch larger impurities while allowing the clean wax to pass through.

Another popular filtration method is using a fine mesh strainer. This method is effective at catching smaller particles and impurities, resulting in a cleaner and more refined beeswax for candle making. Some candle makers also prefer to use commercially available filter discs, which are specifically designed for filtering beeswax. These discs come in various sizes and mesh densities, allowing for customization based on the specific impurities present in the raw beeswax.

Ultimately, the best filtration method for your specific candle making needs will depend on the quality of the raw beeswax you are working with and the final appearance and quality you want to achieve in your candles. It’s important to experiment with different methods and find the one that works best for you. Additionally, consider investing in high-quality filtration equipment to ensure consistent results and high-quality candles every time.

As you explore different filtration methods for beeswax, keep in mind that it’s not just about removing impurities – it’s also about preserving the natural qualities of the beeswax that make it an excellent choice for candle making. With the right filtration method, you can achieve clean and pure beeswax that will enhance the burning experience of your candles while showcasing the natural beauty of this wonderful material.

Overall, understanding different filtration methods and their suitability for your specific candle making needs is crucial in achieving high-quality results. By choosing the right method and using quality materials and equipment, you can ensure that your filtered beeswax enhances the overall quality and appearance of your homemade candles.

The Impact of Filtered Beeswax on the Quality and Appearance of Your Candles

Filtered beeswax plays a crucial role in enhancing the quality and appearance of your candles. By removing impurities, debris, and other unwanted particles, filtered beeswax results in cleaner, more refined candles that burn evenly and emit a pleasant aroma. This section will explore the impact of filtered beeswax on candle making and provide insight into how it can elevate the overall quality of your handcrafted candles.

Enhanced Aesthetics

One of the most noticeable effects of using filtered beeswax in candle making is the improved aesthetics of the final product. Filtered beeswax produces candles with a smooth, polished finish, free from specks or discoloration caused by impurities. The absence of debris ensures that your candles have a uniform color and texture, giving them a more professional and visually appealing look.

Improved Burning Performance

Filtered beeswax contributes to better burning performance in candles. Without impurities present, filtered beeswax burns more cleanly and evenly, resulting in a longer-lasting candle with minimal soot or smoke. This not only enhances the overall user experience but also reduces maintenance and cleanup associated with poorly burning candles.

Heightened Scent Release

The filtration process removes any lingering odors or contaminants from raw beeswax, allowing for a stronger and more pure scent release when the candle is lit. Whether using essential oils or natural fragrances, filtered beeswax provides a neutral base for scent infusion, ensuring that the intended aroma is prominent without interference from unwanted odors.

Additional Resources and Further Reading on Beeswax Filtration Processes for Candle Making

Filtering beeswax for candle making is a crucial step in the process that cannot be overlooked. As discussed in this article, understanding the importance of this filtration process is key to producing high-quality candles. The impurities found in raw beeswax can negatively impact the appearance and burning quality of the candles, which is why it is essential to filter them out effectively.

To achieve the best results when filtering beeswax for candle making, it is important to have the necessary equipment and materials, as outlined in this article. Following a step-by-step guide can also help you achieve optimal filtration results. Additionally, being aware of common mistakes to avoid and learning about different filtration methods can further improve your candle making process.

Filtered beeswax not only enhances the quality and appearance of your candles but also ensures a clean burn. By removing impurities, you are left with pure beeswax that contributes to a longer-lasting and better-performing candle overall. Whether you are a beginner or experienced candle maker, understanding how to filter beeswax for candle making will undoubtedly elevate your craft.

As you continue your journey into candle making, it is beneficial to explore additional resources and further reading on beeswax filtration processes. This will allow you to delve deeper into the topic and gain more insight into achieving the best results when filtering beeswax for candle making. Remember that continuous learning and improvement are essential in any craft, so make use of these resources to enhance your skills in beeswax filtration for candle making.

Frequently Asked Questions

What Is the Best Way to Filter Candle Wax?

The best way to filter candle wax is to use a double boiler method. This involves melting the wax in a double boiler, then pouring it through a fine mesh strainer or cheesecloth to remove any impurities or debris. This helps ensure that the wax is clean and ready for use in candle making.

Can You Filter Beeswax Through a Coffee Filter?

It is possible to filter beeswax through a coffee filter, but it may not be the most efficient method. Beeswax can be quite thick and sticky, which may clog up the coffee filter and make the process slow and tedious. It would be more effective to strain beeswax using a fine mesh strainer or cheesecloth instead.

How Do You Strain Beeswax?

Straining beeswax can be done by melting it in a double boiler and then pouring it through a fine mesh strainer or cheesecloth into a container. This will help separate any impurities and debris from the beeswax, leaving it clean and ready for use in various applications such as candle making, skincare products, or woodworking finishes.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.