Soap And Candle Making Supplies Wholesale

There are many reasons to start a soap and candle making business. Perhaps you are looking for a new and exciting way to make a living. Maybe you are looking for a way to be more self-sufficient and to reduce your dependence on others. Or, you may simply enjoy making soap and candles and want to share your creations with others.

Whatever your reasons, starting a soap and candle making business is a great way to turn your hobby into a profitable enterprise. The key to success is to find a reliable supplier of soap and candle making supplies wholesale.

When you buy your supplies from a reputable supplier, you can be sure that you are getting high-quality products that will help you produce the best possible results. In addition, a good supplier will offer you a wide variety of products, so that you can find everything you need in one place.

A good supplier will also be knowledgeable about the products they sell, and will be able to offer you helpful advice and tips. So, if you are just starting out in the soap and candle making business, be sure to find a good supplier who can help you get started on the right foot.

Scent Candle Making

The art of candle making has been around for centuries. It is an ancient craft that is still popular today. There are many different ways to make candles, but the most popular method is to use a wax, a wick, and a heat source.

The first step in making a candle is to choose the wax. There are many different types of waxes to choose from, including paraffin, soy, beeswax, and gel. Paraffin is the most popular type of wax because it is inexpensive and easy to work with.

The next step is to choose the wick. The wick needs to be the same width as the candle container. There are many different types of wicks to choose from, including cotton, paper, and braided.

The final step is to choose the heat source. The most popular heat source is a candle flame, but a stove top or oven can also be used.

The wax is melted in a pot or a microwave and then poured into the candle container. The wick is then inserted into the wax and the heat source is turned on. The wax will melt and the wick will start to burn. The flame will heat the wax and cause it to melt. The wax will then start to flow up the wick and the candle will be ready to use.

The Candle Making Shop Alnwick

is a professional candle making retailer that supplies high quality candles to customers all over the UK. The shop is based in the historic town of Alnwick in Northumberland and offers a wide range of candles, candle accessories and gifts.

The candle making shop has been trading since 2009 and is a family-owned and operated business. The shop is open 7 days a week and offers a friendly and personal service to its customers.

The candle making shop stocks a wide range of candles, including:

-Scented candles

-Bath bombs

-Soap

-Candle accessories

-Gift vouchers

The candle making shop also offers a bespoke candle making service, where customers can choose their own scent, colour and style of candle.

The candle making shop is a member of the British Handmade Soap and Candle Association and the National Candle Association.

Youtube Making Beeswax Candles

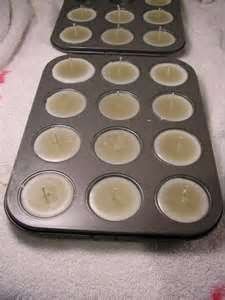

Beeswax candles are made by melting beeswax and pouring it into a mold. The wax can be poured into a variety of shapes, such as a votive, pillar, or taper.

The most important factor in making a good beeswax candle is the temperature of the wax. Beeswax candles should be melted at a temperature of between 160 and 180 degrees Fahrenheit. If the wax is too hot, it will be difficult to pour and the candle will be prone to burning. If the wax is too cold, it will be difficult to form and the candle will be prone to breaking.

When melting the beeswax, it is important to add a small amount of fragrance or essential oil. This will give the candle a pleasant smell.

The wick of the candle should be placed in the center of the wax. If the wick is not in the center, the candle will not burn evenly.

Once the wax has been poured into the mold, it is important to let the candle cool for at least 12 hours.

Wicking For Candle Making

When making candles, it is important to use wicks that are the correct size and type for your candles. In addition, the wick must be properly “wicked” in order to provide a good flame and ensure that the wax is burned evenly.

There are three main types of wicks for candles: cotton, fiberglass, and lead. Cotton wicks are the most common type, and they are made from twisted strands of cotton fiber. They are usually the most affordable wicks, and they are easy to light and tend to burn evenly.

Fiberglass wicks are made from glass fibers, and they are often used in candles that require a long burning time, such as soy candles. They are also popular in candles that produce a large amount of heat, such as pillars and tealights. Fiberglass wicks are more expensive than cotton wicks, but they are more durable and less likely to tangle.

Lead wicks are not as common as cotton or fiberglass wicks, and they are usually used in candles that are meant to be burned on a plate or in a dish. Lead wicks are more expensive than other types of wicks, and they must be handled with care because they can be dangerous if ingested.

In order to wick a candle, you will need a wick, a pair of scissors, and a heat source. First, cut the wick to the desired length. Then, use the scissors to create a “wick tab” at the top of the wick. The wick tab is a small piece of the wick that will be used to light the candle.

Next, dip the wick into the wax, making sure to submerge the wick tab. Hold the wick in place for a few seconds so that the wax will stick to the tab. Then, use the heat source to melt the wax. The heat will cause the wax to flow up the wick, and the wick tab will light the wax.

Once the wax is melted, you can blow out the flame and let the candle burn. Be sure to trim the wick regularly, as needed, to ensure that the candle burns evenly.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.