Wax candle making molds are an essential tool for those wanting to make unique, homemade wax candles. These molds come in various shapes and sizes and can be used to create a variety of looks. The most common type of mold is a block that simply requires filling with melted wax and allowing it to cool.

Alternately, there are complex silicone designs available that produce detailed and intricate figures which require patience and creativity for their successful results. There are also molds specifically designed for making floating candles, large pillar candles or multiple tapers.

One important consideration when purchasing wax candle making molds is the material from which they are made. Common materials include plastic, wood or metal however it is best to avoid plastic due to its tendency to warp or melt.

Aluminum, stainless steel or aluminium/tin mixes offer high quality results while other materials such as plaster of Paris may also be suitable depending upon the desired look of the finished candle – some highly detailed designs may be best suited to this type of mold.

Additionally, the size of the mold needs to be taken into consideration based on how much wax will need to fit into it so that enough surface area of the candle can release heat as necessary during cooling.

It is also important to consider how easy a given mold will be to clean afterwards – silicone molds have become increasingly popular due to their packaging flexibility although they form a tighter bond with their surroundings than others meaning it is especially important that extra care has been taken in application during their use otherwise removal becomes tricky.

In contrast, metal molds tend to make patterns with sharper edges resulting in less definition at certain points but usually these molds are easier when comes time for cleaning up thanks to their non-stick properties.

Types of Wax Candle Making Molds

Wax candle making molds are a popular choice for people who want to make homemade candles. Candles are beautiful and the creative elements can add a lovely touch to any celebration or atmosphere. With so many different types of molds available, it can be difficult to choose the right one for your project. Here is a summary of some of the main types and their features, as well as potential cost considerations.

Aluminum Molds

Aluminum molds are the most common wax candle making molds used by professionals and hobbyists alike. They are typically inexpensive compared to other materials and they come in a variety of shapes, sizes, and colors. Aluminum molds are also very lightweight and durable, making them great for home use. However, they don’t usually last as long as other materials such as silicone or acrylic if you plan to use them often.

Silicone Molds

Silicone molds offer superior heat resistance when compared to aluminum wax candle making molds. These molds come in all sorts of intricate shapes, which makes them perfect for artistic creations that require unique designs and color combinations. Silicone also has excellent durability; however they do tend to be quite expensive when compared with other materials like aluminum or acrylic.

Acrylic Molds

Acrylic wax candle making molds offer great flexibility; as they can easily be manipulated in order to create complicated shapes without being brittle or liable to breakage like glass molding materials might be. They can also be painted in various colors giving them an eye-pleasing effect that looks especially nice when combined with adornments like glitter or sequins.

The only downside here is that these molds tend to be more expensive than both aluminum and silicone ones due to their durability factor and versatility in design options.

Benefits of Using Wax Candle Making Molds

Using wax candle making molds is a great way to make candles easily and quickly. For those new to candlemaking, using molds is an excellent choice. Experienced candle makers often use molds, too, as they can create perfect shapes every time. Wax candle making molds not only make the process of creating a candle easier and more pleasurable but also provide the many benefits below:

- Pre-formed designs – using wax candle making molds eliminate having to set up intricate designs on your own.

- Consistent shapes – with wax candle molds, you don’t need to worry about imperfects in the shape of the candles since each will come out exactly the same.

- Time-saving – instead of having to mold the candle into shape by hand, it takes far less time when pouring it into a mold. Additionally, small amounts of excess wax can be saved and stored for future pourings.

Those who have used wax candle molds before swear by them. Angie R., professional event planner, has had nothing but good results with her cast candles: ““I’ve been using a number of different types of waxes for my cast candles and I’ve yet to experience any problems when working with these molds. The products turned out perfectly.”

Similarly, Suzi M., professional baker loves how easy it is to work with them: “The versatility and convenience that comes with working with these casts just cannot be beat.

I love using them for my special occasion projects.” She further adds that if she has extra time she uses them just for fun: “I enjoy decorating my own home as well as giving away personalized gifts, so I often turn to these casts when I have some free time in hand.

It couldn’t be simpler.”

For those looking for something unique or special item Lisa P., interior designer suggests that you try casting your own custom designs: “Creating custom pieces from scratch can be so much fun; you can add your favorite color or design elements that you won’t find anywhere else. It adds an artistic touch without breaking your budget.”

With countless different types of wax on the market ranging from traditional beeswax to modern eco-friendly soy/coconut blends available these days one could let their creative imaginations run wild.

Candles made from beeswax are known for their amazing scent while vegetable based blend options offer longer burn times at lower temperatures – a real plus for those worried about fire hazards No matter what kind of wax you decide on using there are sure to have plenty good choices available all catering to various budgets and skill levels.

How to Choose the Right Wax Candle Making Molds

Wax candle making molds are necessary when crafting the perfect candle, whether it’s for a special occasion or just to have around the house. It’s important to learn what types of molds are available and how to select the right one for desired results.

When selecting wax candle making molds, there are four main types: aluminum, plastic, silicone and natural latex rubber molds.

- Aluminum Molds – are non-stick with an easy release finish so that candles can be removed without any mess. They come in a variety of sizes and shapes, including spheres, squares, round cylinders and tapers.

- Plastic Molds – generally have deep sides which make them perfect for holding more wax than other molds. Unlike some metals that may discolor or stain from heat, plastic molds stay cool to the touch even while using hot wax.

- Silicone Molds – provide an impressive range of options when selecting smaller molds. Candles made with liquid container wax require silicone because they don’t under pressure or warping caused by heat.

- Natural Latex Rubber Molds – produce unique details on candles like swirls and textured designs due to their ability to be easily molded into complex shapes. This type of mold is typically used for votives or pillars since they must hold their shape during cooling.

The size of the mold also should be taken into consideration since it will determine the size and shape of the candle produced. For example, pillar candles require larger molds with wide bases because they must withstand their own weight during hardening without toppling over.

Professional candle makers use different types of wax for certain candles based on fire safety considerations as well as subtle differences in adhesion between specific types of molten wax and particular mold walls. Paraffin or soy waxes tend to provide better adhesion and thus favor clean removal from aluminum or plastic molds.

Moreover, professionals usually use multiplicative pouring techniques such as layering two colors to create attractive patterns when further developing handmade originality in unity with aesthetics. Mold inserts also can greatly improve this process by allowing manufacturers to press intricate designs into expensive layers of material which become part of the designs once poured in place while cooling down.

How to Clean Wax Candle Making Molds

Cleaning wax candle making molds is vital for preserving the molds for long-term use and ensuring that candles made with them are of the highest quality. This step-by-step guide will explain how to properly clean wax candle making molds, in addition to when it is best to dispose of molds rather than attempting to re-use them.

- Step 1: To begin, ensure that all wax residue has completely cooled from your molds. Use a wooden spoon or popsicle sticks to gently tap the sides of the mold so that any remaining wax shatters and falls out.

- Step 2: Set up a double boiler with hot water and place your molds into it. Let your molds remain in the warm water until you see a layer of cooled wax form at its surface; this process liquefies the cooling paraffin so that it can be removed more easily.

- Step 3: Lift your molds from the double boiler and onto newspaper or an absorbent cloth. If necessary, use rubber gloves so that you don’t burn yourself when handling the oily residue. Scrape all traces of remaining wax off of each mold using a metal cheese grater and soda can.

When Should Wax Candle Making Molds Be Disposed Of?

When it comes to candle making molds, not all may be able to be used again even after they have been thoroughly cleaned. If there are deep cracks or blemishes on them then they should be discarded as these weak spots will make it difficult for candles to be formed evenly and stably over time.

Additionally, if there is discoloration on any of the candles or any sort of distorted shape, these are also signs that it may be time to move onto new wax candle making molds instead of attempting repairs on existing ones.

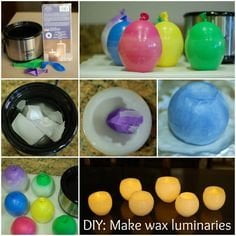

Do-It-Yourself Wax Candle Making Mold Ideas

Wax candle making molds can be made from a range of different materials, and this article will explore some creative ideas for projects using household items. For those looking to add an extra special touch to their homemade wax candles, these do-it-yourself mold options are ideal. People who love the concept of upcycling can use items that would otherwise be discarded to make unique and beautiful wax candle molds.

One of the easiest things to try is pouring melted wax into a glass container such as a reused jam jar, or even a large wine bottle. Once the jar has been filled with the melted wax, it needs to be allowed to cool and cooled off completely before being ready for use. Adding something special and unique can also work well when making molds from these recycled jars.

Decorating by painting or etching on designs are both popular techniques – using an etching cream is one way that can give detailed results of almost any design idea desired. Again, once the design has been complete, allowing the jar adequate time to fully cool is absolutely essential before attempting to remove it from the container as an intact candle mold.

What about kitchen items? Household cupcake pans often make great choices for making wax candle molds too. Here again, decoration is recommended so that your creation stands out. Painting with thick enamel paints on the outside of each cavity will add a great look once your melted wax has been added inside and cooled off.

When it comes time to pop out each individual mold from each cavity, adding a sprinkling of sugar in between layers will allow for easy removal once everything has dried up completely. This way your candle looks more attractive and inviting when you’re finished creating it. With all these suggested ideas in mind you should be well prepared for creating wonderful art pieces with minimal effort needed.

Common Mistakes to Avoid with Wax Candle Making Molds

1. Not Cleaning the Molds It is always a good idea to clean the molds before using them with hot wax. Hot wax residue that is left on the molds can become dangerously flammable if heated again. To clean the molds, it is important to use a cloth dampened with warm soapy water or warm wax remover. The corners of the mold should be particularly well cleaned as this will help prevent air bubbles from forming when pouring in wax.

2. Not Calculating Amounts Of Wax Required Accurately Before making candles, it can be beneficial to have an idea of how much wax is required for each candle shape and size desired.

If too much or too little wax is used, it may lead to uneven shapes and sizes when poured that could upset any pattern design that was intended. It helps to calculate accurately or err on the side of caution – it’s better to have more than not enough.

3. Using Improper Wicking Wicking that is too small or too large can cause numerous issues when making candles with molds as improper wicking can make it more difficult for the melt pool area at the top of the candle to remain properly formed while melting and cooling off.

This can cause vessels such as jars or tins not burning correctly, leading to wasted materials that would need disposing of carefully afterwards. Additionally, setup time may require extra work reselecting wicks and weighing amounts correctly for proper performance after reading through instructions from suppliers themselves for clarification during setup efforts prior.

Conclusion

Wax Candle Making Molds are a great way to create amazing and unique candles. They make it possible for candle makers to produce candles of varying sizes, shapes and designs with minimal effort.

The use of wax candle molds makes the creative possibilities virtually endless as any number of shapes, sizes, and designs can be created. Wax molds come in a variety of styles ranging from basic plastic molds to those made from silicone or resin material, providing an almost infinite array of options for creating unique candles.

When using wax molds, a heat source such as a hotplate or stove is required to melt the desired wax prior to pouring it into the molds. This allows for complete control over how much is poured into the mold and ensure that no air bubbles form during pouring or cooling stages.

It is important to also check that the temperature of the wax remains consistent while in the mold; this can be accomplished by lightly tapping on the side; if there are small bubbles visible in the walls of the mold these should be broken before allowing it to cool completely.

In addition to utilizing a variety of wax molds, many experienced candlemakers choose to design their own soaps and labels to go along with their candle creations. Designing these materials may involve photo manipulation tools like GIMP or Adobe Photoshop, designing textiles for wick holders, printable cut-outs which need art supplies like markers and brushes or even adding custom scents and colors when possible.

Utilizing these tools allows for even further customization with wax-candle making projects; thus offering further potential for creativity beyond what traditional store-bought models offer.

For those interested in learning more about creating unique wax-candles using custom-made molds, there are several valuable online resources available including detailed instructional videos on sites such as YouTube, forums dedicated to discussing topics related to candle making and websites that list where various types of specialty supplies (including molds) can be purchased at discount prices from reliable vendors worldwide. Furthermore Reader’s Digest has published an excellent “DIY” guide book aptly titled ‘Candles.

How To Make Beautiful Candles That Give Light And Aroma’. Overall we have seen that there is a large variety of options available when it comes to creating unique candles using different shaped molds – a hobby which offers tremendous satisfaction through creative experimentation plus potential fulfillment from making some extra cash by selling one’s own beautiful handmade candles.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.