Introduction to Wax Melting

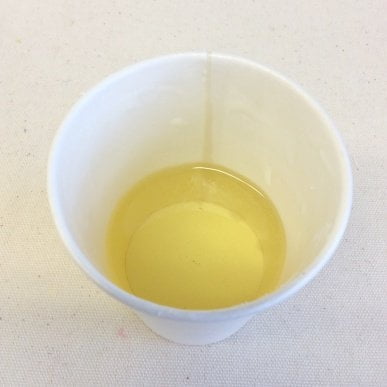

Wax melting is an essential part of candle making as it allows you to liquify the wax so that it can be poured and molded into candles. There are a few options for wax melting, such as using a double boiler or an electric wax melter. When using the more traditional double boiler method, a container of natural beeswax is placed over boiling water until melted. For bigger batches, a dedicated wax melter with adjustable heating temperatures is best.

When using your chosen wax-melting method to make candles, it is important to remember that heat should be applied gradually and evenly throughout the entire surface of the container of open beeswax. This will ensure that it melts slowly and evenly which helps create smooth, level candles when poured into molds or formed freehand. Professional candle-makers often use different physical tools to encourage even melting, such as marble slabs or hot plates placed under the containers they are working with.

Once your wax has melted and reached the perfect temperature, you can add any desired fragrances or colorants before allowing it to cool and harden. The advantages of this technique include improved fragrance distribution when the hot liquid wax reaches the surface of wooden molds during cooling; vibrant colors yield brighter candles using fewer additives; and effective candle performance since there is less risk of air bubbles forming because all ingredients have been incorporated together during one homogenous liquid stage. By adhering to these practices when experimenting with moldable beeswaxes for your hobby or business needs, you should be able to produce brighter colored, longer-lasting scented candles in no time!

Different Types of Wax Melting

There are several different materials used for wax melting when it comes to candle making. The most widely used wax is paraffin, which is a petroleum-based product and usually comes in chunks or pellets. Paraffin makes a great choice for making candles since it melts quickly, is inexpensive, and has no offensive odors. For those looking for a more natural alternative to petroleum-based waxes, soy wax can be a great option. Soy wax is made from farm grown vegetable oils and has a reputation for a clean burn with little odor or smoke. Beeswax is another natural choice for wax melting that gives candles an attractive golden hue and an appealing honey scent. Additionally, palm oil wax has become popular in recent years due to its eco-friendly production methods; candles made of palm oil tend to burn longer than other types of wax and also come with an attractive sheen. Candles made from beeswax blend or beeswax melts can also be found on the market today; these mixtures use combinations of paraffin, soy and beeswax to create a candle that combines the benefits of all three types of waxes into one product. Whichever type of material you choose, the key is to ensure the candle maker uses a good quality product that will increase the life span and performance of their homemade creations.

Melting Wax at the Right Temperature

Whether you’re an experienced candle maker or just starting out, it’s important to understand melting temperatures for wax when making candles. Knowing the optimal temperature for melting wax is key for successfully creating high-quality, long-burning candles.

The temperature of the wax when melted will affect your final product in several ways. If you melt the wax too quickly, this can cause tunnelling”where the candle burns down quickly only illuminating its center. Whereas if you melt wax too slowly and then cool it too quickly while pouring, this can lead to a poor scent dispersement due to the pour not being hot enough to absorb the scent correctly. It’s also essential to make sure your wick is big enough for the size of your candle and that it’s placed in the center so that your candle will burn evenly, again avoiding a tunnel effect.

So how do you find the right temperature? Most Waxes are designed around particular melting points so as a general rule, it is best to follow manufacturers guidelines on melting points but, depending on what type of wax you use (Paraffin/Soy/Beeswax) be prepared to adjust temperatures accordingly. Paraffin Wax tends to have a melting point between 120 ” 140°F and Soy Wax 105 -115°F whereas Beeswax has a higher melting point of 140-150°F. To avoid distortion from thermal shock or cracking due to insufficient cooling time; try keeping below recommended maximum temperatures and being really gentle when stirring and pouring colder liquids close by ” as hot liquid can quickly destroy them! Remember that each time you reheat wax some of its properties are lost along with colour or fragrance and this will impact on burn time and overall look & feel of your finished product! Pay particular attention when working with harder waxes such as Beeswax which require higher temperatures during melts but need longer more gradual cooling process than other types ” even turning off heat after reaching max & letting sit while maintaining viewing through heat resistant surface such as Pyrex Jars over electricity stovetop! Finally; always double check manufacturer instructions before starting any project/recipe!

Precautions and Safety

Candle making is a calming and enjoyable hobby, but it does involve working with molten wax which can be dangerous. When melting wax for candle making, it is important to take certain safety precautions in order to protect yourself from injury. Always melt wax on a heat-resistant surface away from any flammable materials and children. When melting wax on the stove, never leave it unattended and always set the burner on a low heat setting to reduce the chance of burning the wax. Keep containers of water or sand nearby in case of an emergency. Additionally, don’t attempt temperatures greater than 375F as this could lead to an explosion. Wear protective clothing such as long sleeves, thick coverings or rubber gloves while pouring molten wax into molds. Be sure not to overfill the moulds or use candles with wicks that are too large as this can result in excessive flame height when lit and pose a fire hazard. Finally, allow finished candles ample time to cool before handling them as hot wax can cause serious burns if spilled onto skin.

What to Do After Melting the Wax

One useful product you can make with melted wax is a dipping mold. This involves melting the wax and then maintaining it at a temperature that’s high enough to pour but not so hot that it will burn your skin. You can also create pillow molds, which involve creating molds for candles of a specific design by pouring in layers of melted wax. These molds can be used to create shapes such as hearts, stars, geometric patterns, and more.

Another great use for melted wax is making layered candles. When making candles with multiple colors or patterns, you can start by layering colored chunks of wax in the bottom of your mold and then slowly drizzle on top layers of melted wax until you have the desired effect.

A third option is to make homemade eco-friendly fire starters. All you need is an egg carton or muffin tins filled with bits of cotton (or dryer lint) covered with melted wax. These are easy to store since they don’t require matches and come in handy when trying to start fires quickly in campfires or fireplace grates.

Finally, some restaurants actually use melted wax for presentation purposes on their menus and dining tables! By using custom-colored poured-wax espresso cups or unique designs on plates, chefs are able to give diners an intriguing show before their meals arrive.

Different Wax Melting Methods

One very popular and effective way of wax melting for candle making is double boiling. This method requires that the wax and its additives are placed into a pan or bowl, then another larger pot or pan is filled with water and the first one is placed within it. Both containers are then heated, causing the temperature of the wax to rise slightly and melt completely. As this method does not require direct heat application to melt the wax, it is considered safer to use.

Another wax melting technique commonly used in candle making is using a microwave oven. This can be done either by using a specific microwave-safe container or through directly applying heat on parchment paper which can be safely put in a microwave. In this case, power levels should usually be kept low, as too much heat may cause discoloration of the wax shreds. Also when doing any kind of heating in a microwave, it’s ideal to keep an eye on the process at regular intervals to avoid over-heating and damaging the wax.

A third option for melting wax would involve investing in specialized tools such as electric melters or hot plates which aid in controlling temperatures better and allow for prolonged exposure to heat while melting the wax quickly and efficiently throughout large batches of candles all at once. Pre-packaged pre-blended paraffin & soy wax flake blends are available for these types of long melting processes making them convenient for those interested in taking their candle making projects up a level without worrying about manually measuring ingredients or having to deal with equipment failure due to high temperatures caused by extended exposure to heat.

Common Mistakes to Avoid

When melting wax for candle making, it is important to avoid common mistakes that can result in a poor quality candle. One mistake many people make is not using the correct temperature when melting the wax. It is vital that the temperatures are monitored accurately and not exceeded when melting wax as this can cause the wax to get too hot, resulting in weak candles with poor burning characteristics.

Another mistake to avoid when melting wax is not stirring the wax regularly while it is melting. Not stirring regularly can cause air bubbles to become trapped inside the wax, making it more difficult to form a good quality candle. Additionally, if you are using additives such as fragrances or colors then they should be added after melting and thoroughly stirred before being poured into molds. Adding color or fragrance before fully melted could lead to a poor result once finished candles are produced.

Finally, make sure you use an accurate thermometer when measuring the temperature of your melted wax. If an inaccurate thermometer is used then you may produce a faulty batch of candles since different types of wax should be melted at different temperatures for optimal results. Allowing your melted wax to cool properly before pouring it into molds will also benefit your final product significantly by improving burn performance and creating better looking candles overall.

Conclusion

Wax melting is an essential part of candle making. The process of melting wax enables one to create their desired candles, with the freedom to mix colors, scents and shapes. People can form their own unique candles using this process. Wax melting is beneficial for a variety of reasons. First, it makes the wax easier to pour and manipulate in order to create different shapes and sizes. Second, it allows for quick cooling times for specific candles. Third, because of its malleability, it allows for a wide range of colors and fragrances that can be added to the candle for personalization. Lastly, the melting process itself can add longevity and stability to more delicate candles providing peace of mind that they won’t break or melt too quickly when lit by a flame. All these factors make wax melting invaluable in helping shape creative and long lasting candle designs customized specifically by the maker.

In conclusion, wax melting is extremely beneficial in candle making due to its ease of use and customizable capabilities. From controlling the size and shape of the candles being made to adding color or scent to give them personality – all this is achievable through wax melting! With these advantages in mind while creating their next masterpiece, any individual looking into making a custom candle will certainly benefit from understanding the advantages that come with utilizing hot wax as part of their craftsmanship arsenal!

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.