Introduction to Aluminum Candle Making Pouring Pot Manufacturer

Aluminum candle making pouring pots are essential tools for creating beautiful, high-quality candles. As a result, it is important to find an aluminum candle making pouring pot manufacturer that produces the most reliable and efficient cast iron materials. At ABC Manufacturing, we have been producing superior aluminum casting technology since 1970. With our vast experience in providing products to many candle makers worldwide, we guarantee you will be satisfied with the quality and craftsmanship of our aluminum pouring pots.

Our aluminum candle making pouring pots are designed to meet the highest safety standards while also providing superior heat dispersion and temperature control. The lightweight construction allows users to quickly move the product around their workspace with minimal effort. Additionally, each pot has been fitted with a spout for easy pouring and a metal handle for user convenience. Plus, all of our products come backed with a one-year warranty so you can rest assured that your money is well spent.

At ABC Manufacturing, we use advanced methods to cast our aluminum structural components while also paying close attention to detail during the finishing process. We conduct stringent testing on all of our materials before shipping out in order to eliminate potential defects or imperfections. Our team is always available if you require assistance selecting the right size or shape for your project needs as well. We look forward to assisting you with your next candle-making venture!

Benefits of Aluminum Candle Making Pouring Pots

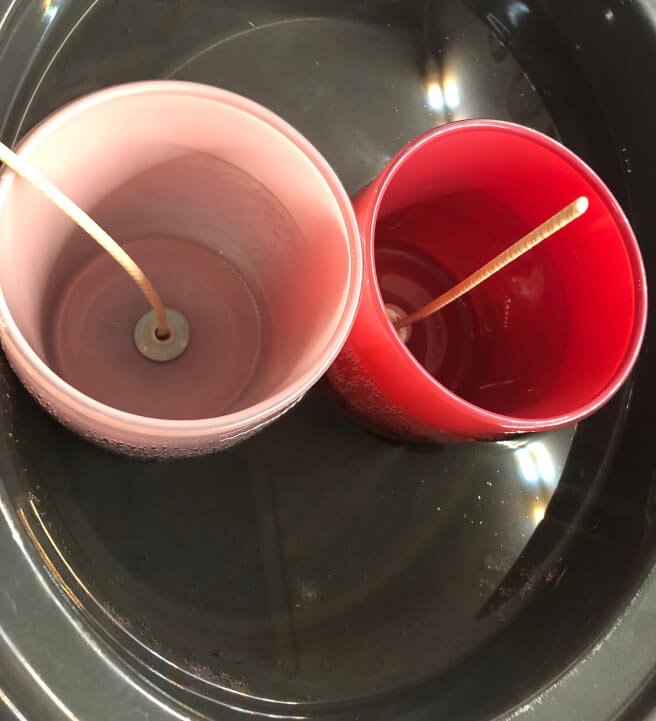

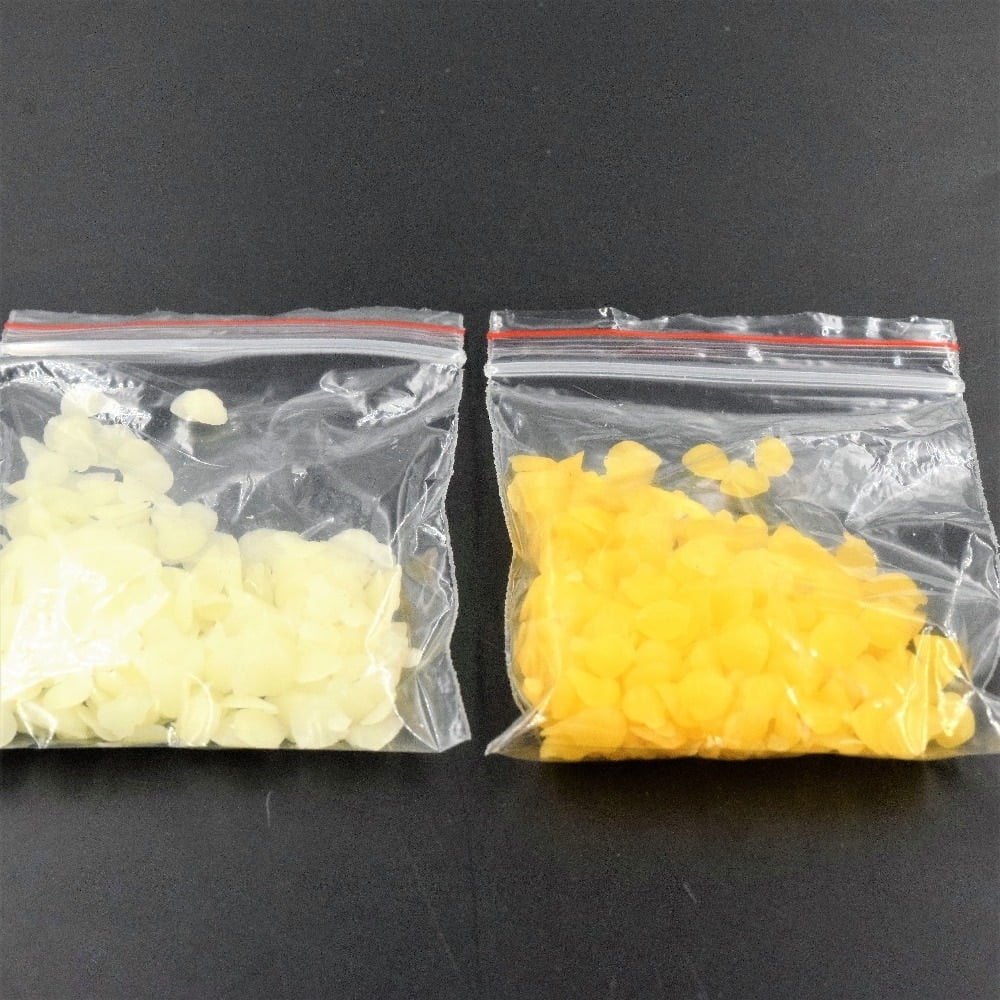

Aluminum candle making pouring pots are essential pieces of equipment for any candle maker. They provide a safe and convenient way to melt wax, pour it into your molds, and mix in colors and fragrances. There are many benefits to choosing an aluminum pouring pot over other materials for your candle making needs, including:

1. Lightweight and Durable – Aluminum pouring pots are lightweight yet very durable. This means they will not easily dent or break, which is great news if you’re working with hot wax.

2. Heat Retention – Since aluminum is a good conductor of heat, these pouring pots retain the heat of the melted wax better than other materials. This prevents it from cooling too quickly as you’re working, allowing your candles to set up properly with less mess.

3. Cost Effective – Aluminum pouring pots are highly cost-effective for candle makers on a budget since they don’t require frequent replacement due to wear and tear like plastic models do, saving money in the long run.

4. Easy to Clean – Unlike more intricate designs such as steel or brass pots, aluminum pouring pots are much easier to clean as there aren’t as many hard-to-reach areas where excess wax can accumulate.

5. Variety of Sizes Available – After comparing different manufacturers, you can choose from a variety of sizes ranging from small to large depending on your individual needs.

Different Sizes and Shapes of Aluminum Candle Making Pouring Pots

Aluminum candle making pouring pots are becoming an increasingly popular choice for candle makers. An aluminum pot is great because it is light, whereas other materials such as ceramic, can be quite heavy and difficult to move around when casting candles.

These types of pouring pots come in all different shapes and sizes. The size will depend on how much wax you need for your project, the particular type of wax being used, and how many candles you plan on casting at one time. Some commonly made shapes include round or square bases with a spout for precise pouring. There are also larger circular versions that allow for larger batches of candles to be poured at once.

The practical aspects aside, aluminum pouring pots offer a unique style as well due to their sleek and silver appearance. This can give any room a modern touch that contrasts nicely against more rustic-style candles and decorations. With so many options available in terms of sizes and shapes, you can easily customize your own piece according to the style of your space or project requirements.

Features to Look for in an Aluminum Candle Making Pouring Pot

When purchasing an aluminum candle making pouring pot, there are several features to look for.

One feature to consider is size. Look for a pot that is wide enough for the type of candles you are making and deep enough to hold the wax without overflowing.

Another important feature to consider is a lid. A lid helps keep the wax contained, prevents spills and helps maintain the perfect temperature for pouring.

A spout is another essential feature. Look for a pot with an ergonomically designed spout that will allow you to easily pour the melted wax into your molds without spilling it or splattering it around your work area.

Safety is also key when selecting an aluminum candle making pouring pot; make sure that there are heat-resistant handles on the sides of the pot to help prevent burns when moving it from one place to another. Additionally, take into account any extra safety features such as a non-slip base or insulated coating so that the pouring pot will not slide when handled or moved once it has been heated up with melted wax inside.

Finally, if you are looking for something more durable and long-lasting, look for an aluminum candle making pouring pot made out of food grade material as well as being free of chemicals such as lead or phthalates which may produce harmful vapors when heated up during production.

Reasons to Choose an Aluminum Candle Making Pouring Pot Manufacturer

Choosing an aluminum candle making pouring pot manufacturer is a wise decision for many reasons. Firstly, aluminum has excellent thermal properties, making the material perfect for withstanding extreme temperatures like those required for candle-making. Additionally, aluminum is extremely light and easy to work with, allowing manufacturers to create pour pots quickly and efficiently. Finally, aluminum is cost efficient compared to other materials that could potentially be used in the same application. The combination of these qualities makes using an aluminum candle-making pouring pot manufacturer an ideal choice when looking to produce candles in large quantities.

How to Find the Right Aluminum Candle Making Pouring Pot Manufacturer

Finding the right aluminum candle making pouring pot manufacturer for your business can be a daunting task. The first step in finding the best supplier is to research different manufacturers and ask questions about their manufacturing processes, product availability, and other important information.

When researching potential suppliers, it is important to find out the types of aluminum they use. This could mean looking up specific specifications such as grade and alloy type. It is also a good idea to look at their quality control measures and if they offer any certifications that guarantee a certain level of quality in the materials they use. Additionally, check if they have references that can vouch for the reliability of their products and services.

Another factor to consider when researching potential suppliers is their delivery lead time. Find out how quickly they deliver orders so you can plan accordingly and make sure you receive products on time. You should also determine if there are any additional charges for shipping or extra costs associated with customization services before making a purchase from them.

Finally, it is worth investigating what services are provided by each supplier – this includes post-purchase customer service such as repairs and replacements in case something goes wrong with the candles made from their products. Finding someone you feel comfortable working with who has an excellent track record of customer service will help ensure your satisfaction in the long run!

Tips for Choosing the Best Aluminum Candle Making Pouring Pot

When selecting an aluminum candle making pouring pot, it’s important to consider the quality of the material. You want to choose a pot made from high-grade aluminum that can withstand the heat of candlemaking and won’t suffer from dents or damage easily. Look for stitching that is neat and even, with no gaps or weak points. Look for a good handle for easy gripping and pouring, since this pot may become quite hot. Also make sure the pour spout has no drips or leaks and remains flat while pouring. It is also worth checking the manufacturer’s warranty – many offer long-term guarantees of quality that can give you peace of mind when buying your aluminum candle making pouring pot.

Ways to Get the Best Deals on Aluminum Candle Making Pouring Pots

1. Shop around: To get the best deals on aluminum candle making pouring pots, it’s important to take the time to shop around. Compare prices from different manufacturers, and look for any promotions or discounts that may be available.

2. Purchase in bulk: Many aluminum candle pouring pot manufacturers offer volume discounts when you purchase multiple items at once. If you plan on making lots of candles, it may be worth taking advantage of such offers in order to save money in the long run.

3. Know what size you need: Before shopping for an aluminum candle pouring pot, it’s important to know what size you need so that you can budget appropriately. Sizes vary greatly among models, so make sure that the one you choose is large enough to meet your needs while still fitting within your budget.

4. Look for discount codes: When searching online for aluminum pouring pots, it pays to spring up unexpected savings such as free shipping offers or valuable coupon codes from candle manufacturing suppliers. Take advantage of these discounts whenever possible to lower costs further when buying a new pot.

5. Check reviews: Lastly, be sure to research customer reviews before purchasing an aluminum pouring pot from any manufacturer in order to ensure a good quality product and robust after-sale service if needed.

Essential Safety Tips for Using Aluminum Candle Making Pouring Pots

1. Always use the right size pouring pot for your candle making project. Make sure that the pot is large enough to contain all of the wax, fragrance, and other materials you will be using in your candle making process.

2. Make sure that the area you have chosen for making your candle has proper ventilation and no potential fire hazards such as curtains or paper near the pot.

3. Double check that your pouring pot is on a stable surface with no risk of tipping over during the heating process.

4. Once you have placed your pot on a suitable burner only use a low heat setting to prevent wax from splattering due to overheating.

5. Never leave an unattended candle making pouring pot unattended as there is always some risk of fire or injury associated with burning wax even at low temperature settings.

6. When it is time to remove any excess wax from the bottom of your pouring pot, ensure that it is cool enough to touch before attempting this as hot wax can cause burns if mishandled.

7. Always use gloves when handling any type of heated kitchen utensil including aluminium poured pots for safety and comfort reasons not just when dealing with heated liquids but also cooled ones too as fingers can easily slip on smoother surfaces such as aluminium and lead to accidental burns or cuts while handling them during cleaning and other tasks related to candle making using these tools

Conclusion

As an aluminum candle making pouring pot manufacturer, we have been proud to provide quality, reliable products with excellent customer service. We are committed to ongoing research and development of our products so that we can continue to provide the best possible solutions to our customers. Having a wide range of product options means that everyone can find the perfect product for their needs. Our goal is to make sure every customer is happy with their purchase so that they come back for future projects! Thank you for considering us as your supplier.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.